| GA 1 - 2 - 3 - 4 - AP 1 - 2 - 3 - 4 - 5 - NT 1 - 2 - 3 - 4 - 5 - 6 → Vol.1No.2 | ||||

| Vol.1, No.1, NT3

|

||||

Seal-Welding over Cracks for Preventing SCC Propagation |

||||

| Takashi Ito, Hitachi-GE Nuclear Energy, Ltd.

Tooru Ootsubo, Toshiba Corporation |

||||

KEYWORDS: |

||||

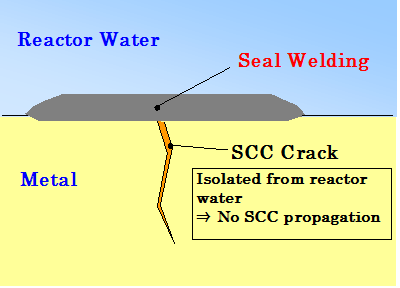

| 1. Technical summary | ||||

| Classification (I: Inspection, II: Repair,III: Replacement, IV: Preventive Maintenance, V: Others) | ||||

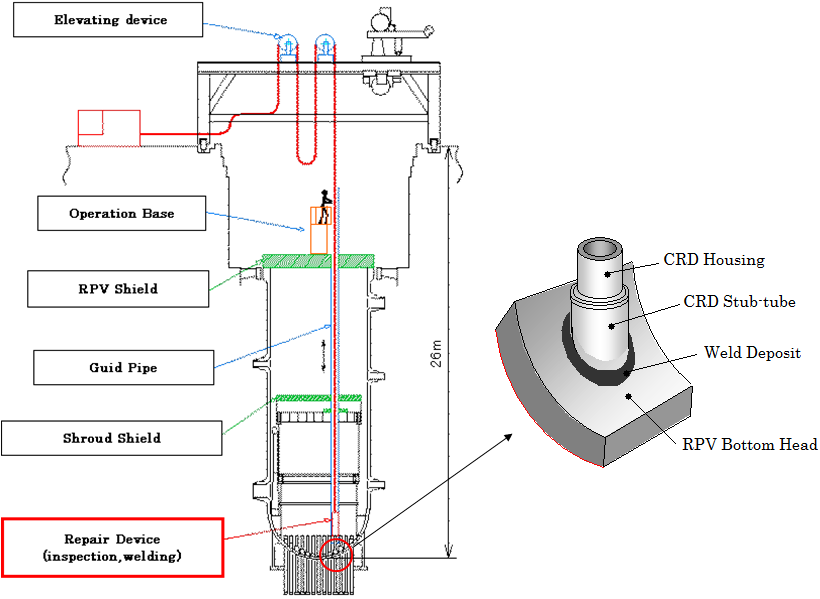

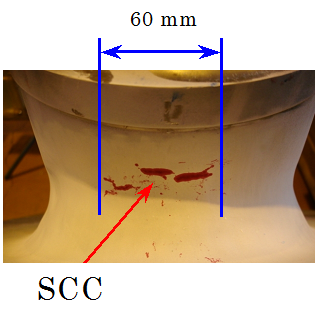

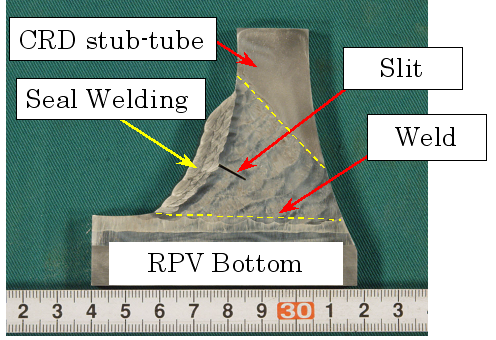

| This repair method overlays and seals an existing crack to prevent its contact with the reactor water. It aims to prevent propagation of stress corrosion cracking (SCC). SCC resistant materials are used for overlaying. Laser welding and TIG welding have been developed as overlaying method. Seal welding method does not need machining / grinding for removing cracks, preparing grooves, nor buttering by weld. This simple method can be applied to narrow location such as lower plenum of BWR, and it takes short time to complete repair work. |

||||

Fig. 2 Image of repairing work for CRD stub-tube |

||||

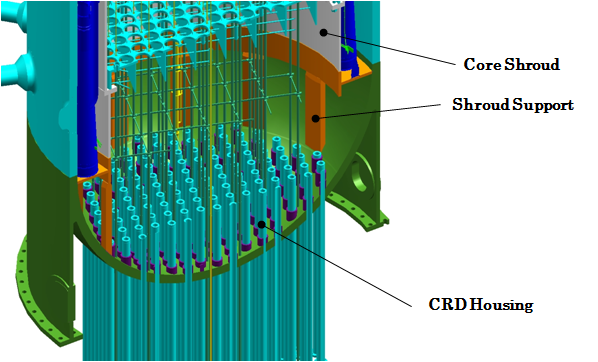

| 2. Scope | ||||

(1) Components (2) Materials (3) Condition

Fig. 3 Lower Plenum of BWR |

||||

| 3. Features | ||||

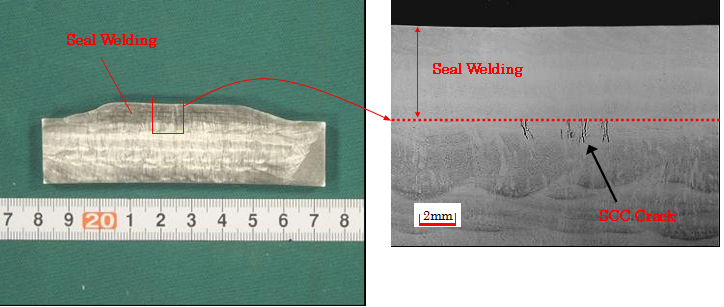

(1)Prevent propagation of exiting SCC crack without removing it

Fig. 4 Image of repairing work for CRD stub-tube

Fig. 5 Examples of CRD stub-tube seal welding mock up |

||||

| 4. Examples of Application | ||||

The method has been applied to a penetration of the control rod drive mechanism of reactor vessel head of a PWR in Japan. |

||||

| 5. Reference | ||||

| Guidelines on repairing methods (seal welding) (JANTI-VIP-01), Japan Nuclear Technology Institute (in Japanese ) | ||||

| 6. Contact | ||||

| Japan Society of Maintenology (ejam@jsm.or.jp) | ||||