Classification

7 - C Dismantling/Decontamination

Presently, robots are deployed in the Fukushima Daiichi Nuclear Power Plant (NPP) for the implementation of survey, measurement and so forth in a high radiation environment within the buildings by remote control. Additionally, in the future it is anticipated that there will be an increasing needs for the robots to be used for the removal of rubbles, installation of shielding and so forth. Furthermore, it is deemed necessary to prepare the robots for the decontamination work required to improve the environment within the buildings, and to apply the robots to the subsequent survey and repair works for reactor containment vessels.

To respond to such needs for the application of remote-controlled robots, development works have been in progress.

This paper provides an introduction to the submersible crawling swimming robot and the shape-changing robot. These are some of the above-mentioned robots developed thus far. The submersible crawling swimming robot is suitable for underwater surveys because this robot can avoid obstacles and inspect wide areas. The shape-changing robot is capable of passing through narrow spaces and crawling stably on rough floors.

- (1) Components:

Reactor building

- (2) Materials: Disaster site

- (3) Location: N/A

- (4) Condition: N/A

(1) Submersible crawling swimming robot

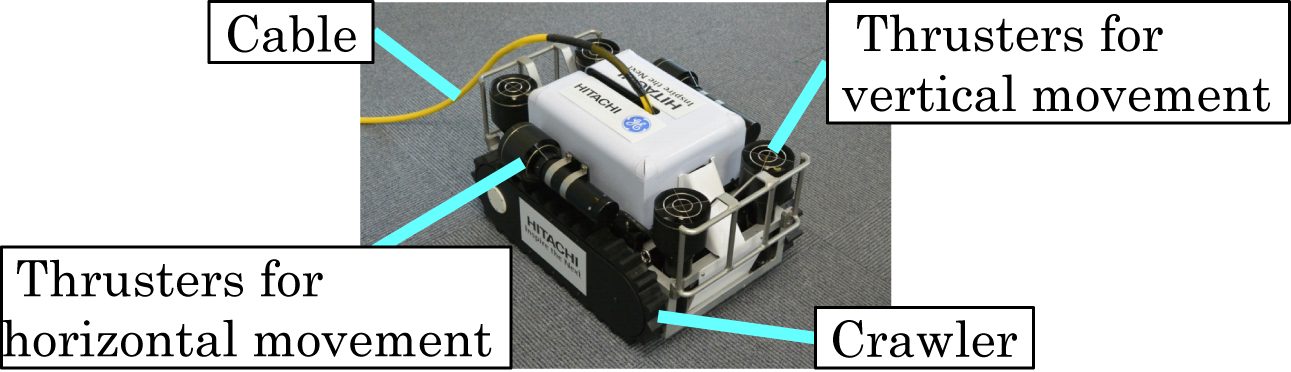

The submersible crawling swimming robot was developed to survey narrow spaces in water environments. In particular, this robot was developed to investigate underwater leakage points of the retained water within a nuclear power plant. Fig. 1 shows a photo of the robot, and Table 1 lists its specifications. The robot has six thrusters and two crawlers. Four vertical thrusters are used for vertical movement, and two horizontal thrusters are used for horizontal movement. The robot can also move on a floor and climb on a vertical wall using crawlers. The dimensions of the robot are length 605 mm, width 450 mm, and height 330 mm. The weight is 31.5 kg in air, and 1.5 kg in water. 80 m umbilical cables are connected to supply power and allow communication with operators.

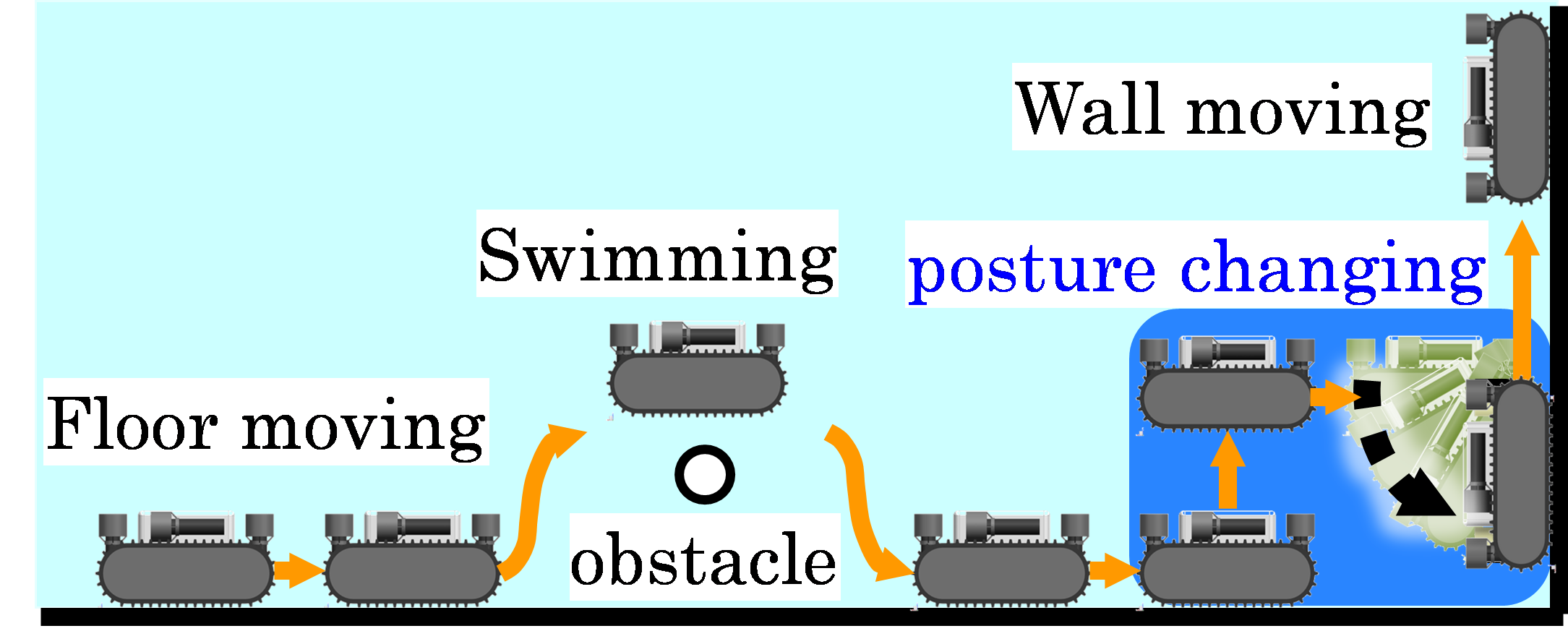

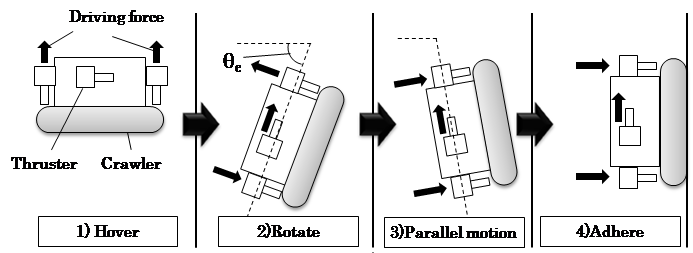

Fig.2 shows movement in water. The robot can swim and change its posture through controlling its thrusters to avoid obstacles and improve accessibility in narrow spaces. Fig. 3 shows the procedures for posture change. The robot hovers close to a wall, and changes its posture 90 degrees by controlling the thrust forces automatically. After adhering to the wall, the robot can crawl using these crawlers.

The position of the center of buoyancy is separated from the position of the center of gravity to stabilize the posture of the robot horizontally. The posture of the robot is easily changed from a stable horizontal posture to an unstable vertical posture by a simple sequence control. Therefore, the operator easily controls the robot by a controller.

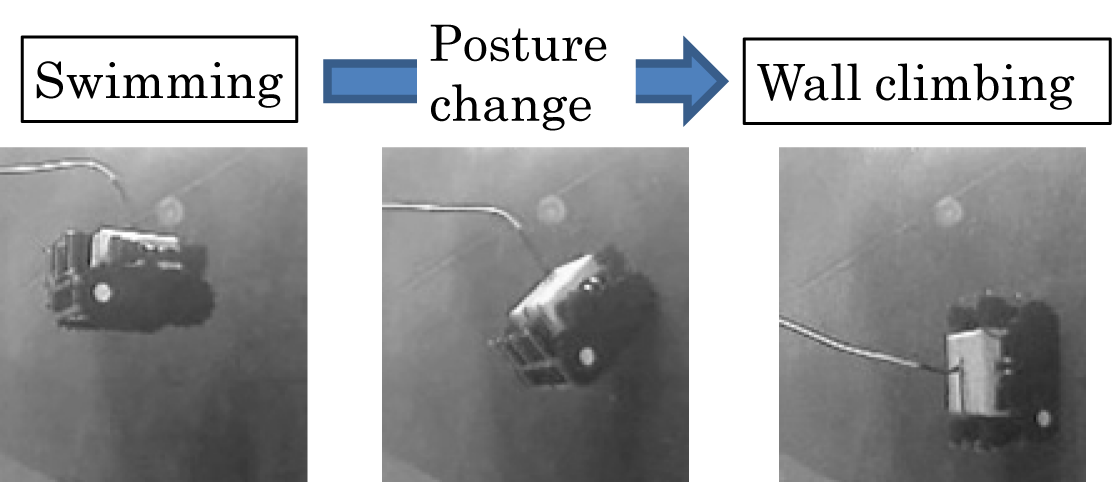

We confirmed that the robot can avoid obstacles in water, as shown in the photos of Fig. 4, by swimming and changing the posture through controlling its thrusters.

A camera and an ultrasonic sensor (sonar) can be mounted on the robot to survey in water environments.

Fig.1 Photo of the submersible crawling swimming robot

| Size(length × width × height) | 605 mm × 450 mm × 330 mm |

| Weight | 31.5 kg (in air); 1.5 kg (in water) |

| Movement system | 6 thrusters: 2 horizontal and 4 vertical 2 crawlers (one pair) |

| Maximum thrust force | 70N |

Fig.2 Movement in water

Fig.3 Procedures for posture change

Fig.4 Photos of posture change in water[4]

(2) Shape-changing robot

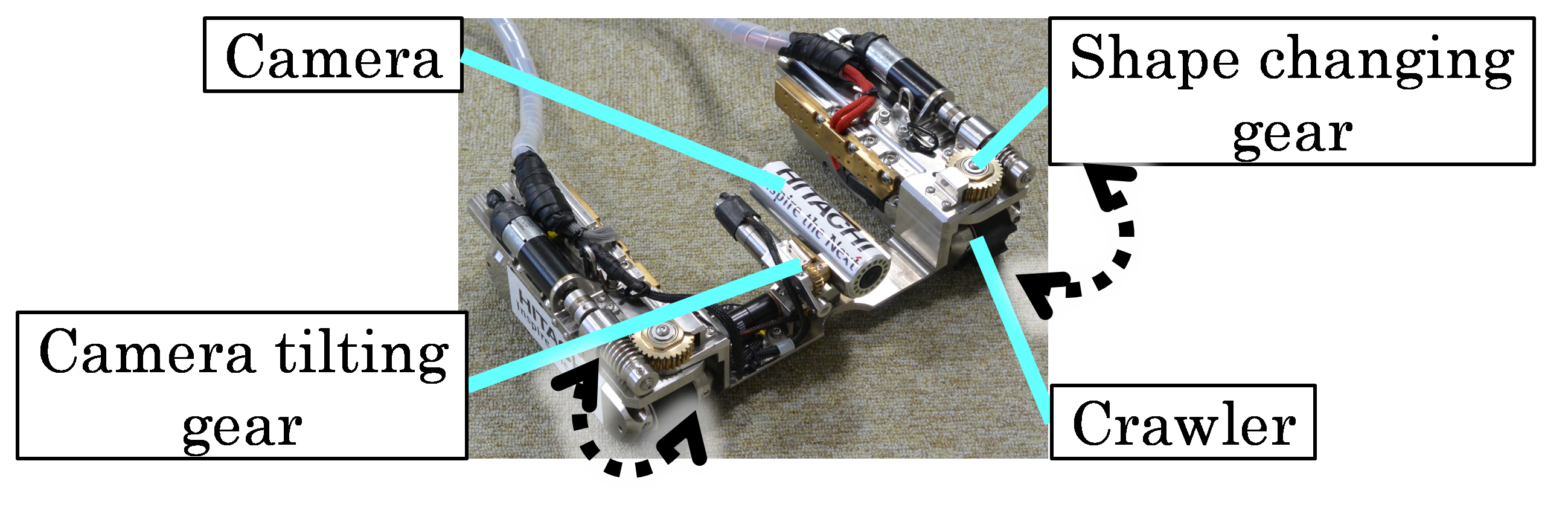

The shape-changing robot was developed to pass through narrow spaces and to carry out surveys while crawling on rough floors. In particular, this robot developed to investigate the inside of PCV. Fig. 5 shows a photo of the robot, and Table 2 lists its specifications. The robot consists of three components, the main body and two compact crawlers. The crawlers are mounted on the body with shape-changing gears. By controlling the gears, the crawler is rotated 90 degree in relation to its body. When two crawlers are arranged in a line (I-shape), its circumscribed circle diameter is less than 100 mm, and the weight is 7.5 kg. Maximum thrust force is 100 N and it is sufficient to pull an umbilical cable.

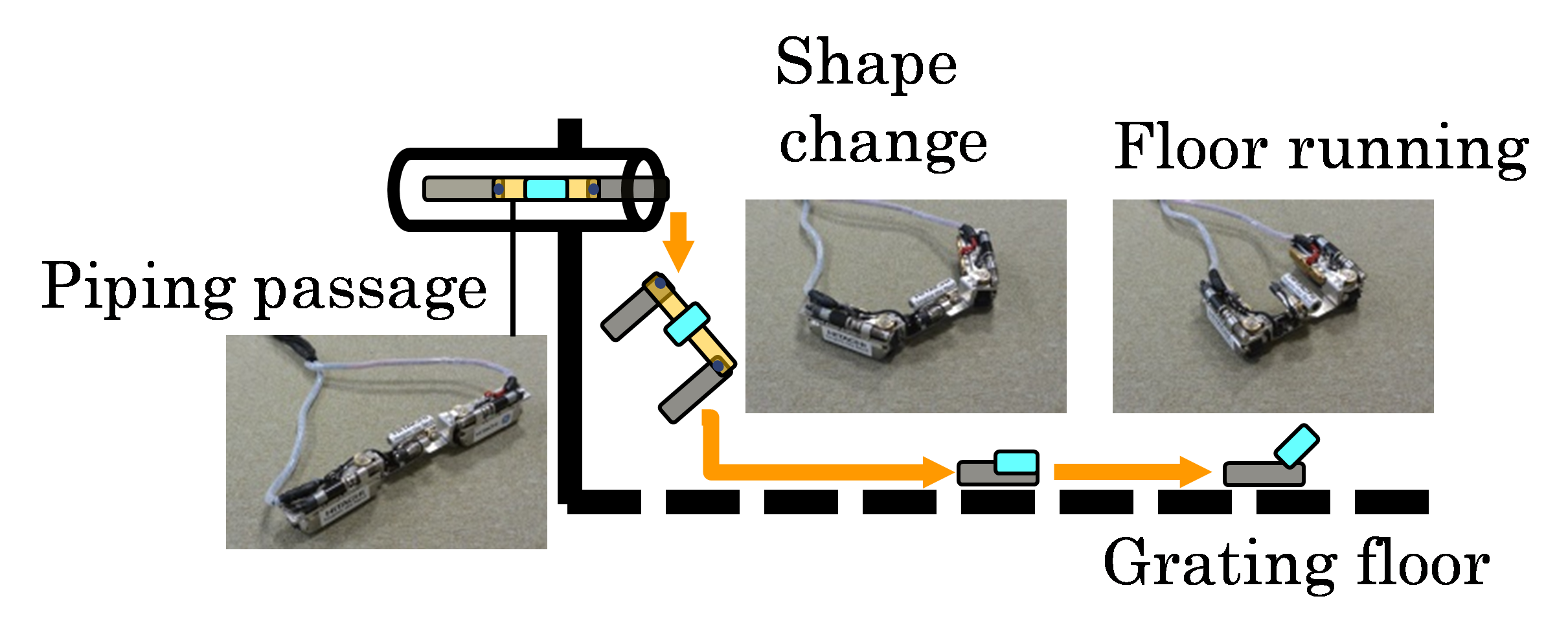

Fig. 6 shows movement of the robot. To pass through narrow spaces such as pipes, the robot changes to the I-shape. After entering the survey area, two crawlers are rotated 90 degree (U-shape) and the robot is able to crawl on rough floors such as grating floors.

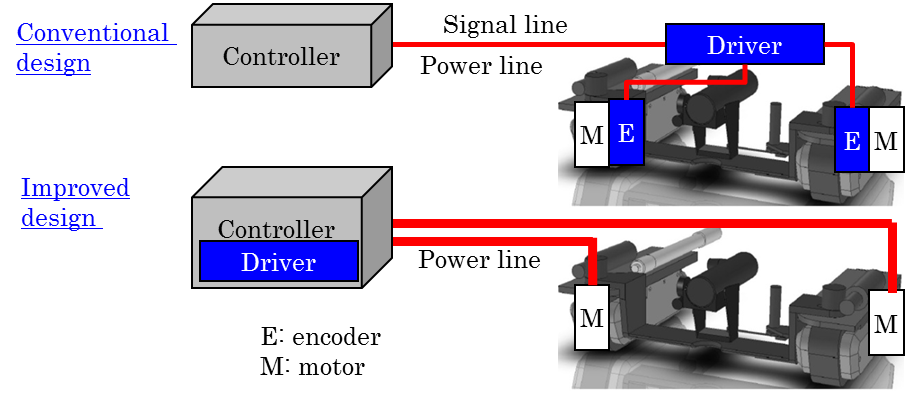

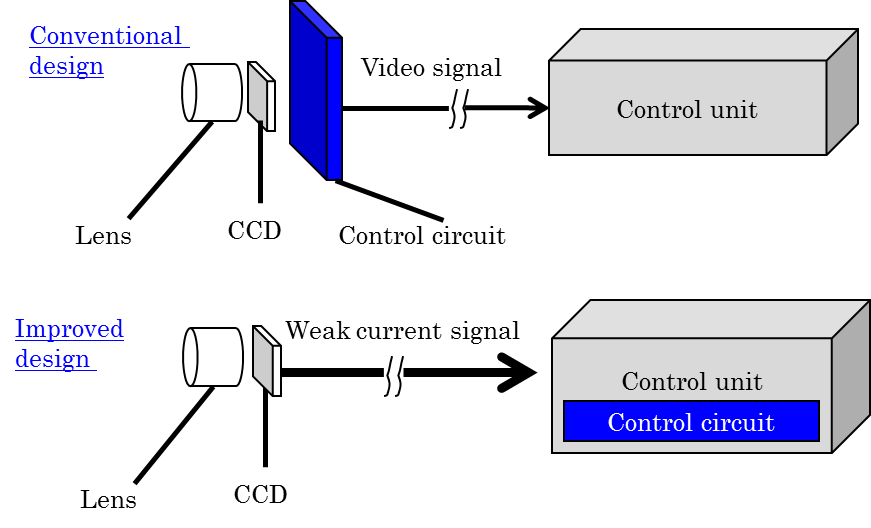

The robot was applied to the survey inside of PCV. The environment was previously found to be a high radiation area. For that reason, most of the electronic devices are separated from the robot and arranged in a low radiation area. Fig.7 and Fig.8 show the configuration of the movement mechanism and the camera unit, respectively. The robot has motors without motor drivers and encoders, and a CCD image chip is mounted on the robot. Therefore high radiation resistance (about 1000 Gy) is achieved.

Fig.5 Photo of the shape-changing robot

| Size(length × width × height) | 90×640×65 for passing through pipes 90×250×272 for moving on floors |

| Weight | 7.5 kg |

| Movement system | 2 crawlers (one pair) |

| Maximum thrust force | 100N for floor running |

Fig.6 Movement of the robot[4]

Fig.7 Configuration of the movement mechanism

Fig.8 Configuration of the camera unit

5. Conclusion

(1) Application to Fukushima Daiichi NPP

We have applied these robots to Fukushima Daiichi NPP for surveying the torus room[5] and the inside of PCV[6]. We confirmed that both robots successfully carried out surveys in narrow spaces.

(2) Future

In the Fukushima Daiichi NPP, there are a lot of high radiation areas in the reactor building. Operators cannot access these areas and work in them directly. Therefore, remotely operated robots are needed to carry out various operations in the future. We are continually developing robots for surveying and carrying out tasks to achieve fuel debris removal.

6. Reference

- [1]Hitachi, Ltd., “Submersible crawling swimming and shape-changing robots for inspection prior to removal of fuel at Fukushima Daiichi Nuclear Plant – Changing shape and posture to avoid obstacle in narrow space --”, Press Release, posted on March 10, 2014, http://www.hitachi.com/New/cnews/month/2014/03/140310e.html

- [2]Hayato MORI et al, “Development of remotely operated robots for decommissioning of nuclear power plants; (1) Development of leakage survey vehicle in torus room”, 2014 Annual Meeting of the Atomic Energy Society of Japan, p.401, 2014.

- [3]Satoshi OKADA et al, “Development of remotely operated robots for decommissioning of nuclear power plants; (3) Development of shape changing robot for inner of PCV survey”, 2014 Annual Meeting of the Atomic Energy Society of Japan, p.403, 2014.

- [4]Nikkan Kogyo Shimbun Webpage

http://www.robonable.jp/news/2014/03/hitachi-0311.html - [5]Tokyo Electric Power Company, “Survey of wall of torus room in Unit 2 in Fukushima Daiichi NPS (Report for demonstration survey in R & D project)”, Handouts at press conference 2014, posted on July 28, 2014, http://www.tepco.co.jp/en/nu/fukushima-np/handouts/2014/images/handouts_140728_05-e.pdf

- [6]Tokyo Electric Power Company, “Development of a technology to investigate inside the Reactor Primary Containment Vessel (PCV) -- Results of site test “Investigation B1” on grating around the pedestal inside Unit 1 PCV –“, Handouts at press conference 2015, posted on April 30, 2015, http://www.tepco.co.jp/en/nu/fukushima-np/handouts/2015/images/handouts_150430_04-e.pdf

Japan Society of Maintenology (ejam@jsm.or.jp)