| GA 1 - 2 - 3 - 4 - AP 1 - 2 - 3 - 4 - 5 - NT 1 - 2 - 3 - 4 - 5 - 6 → Vol.1No.2 | ||||

| Vol.1, No.1, NT5

|

||||

Internal Polishing

|

||||

| TOSHIBA CORPORATION | ||||

KEYWORDS: |

||||

| 1. Technical summary | ||||

| Classification (I: Inspection, II: Repair, III: Replacement, IV: Preventive Maintenance, V: Others) | ||||

| In this technique, inner surface of a pipe is polished in order to improve residual stress. Through the process, residual stress just near the inner surface removes to compression and SCC crack initiation is prevented. | ||||

|

||||

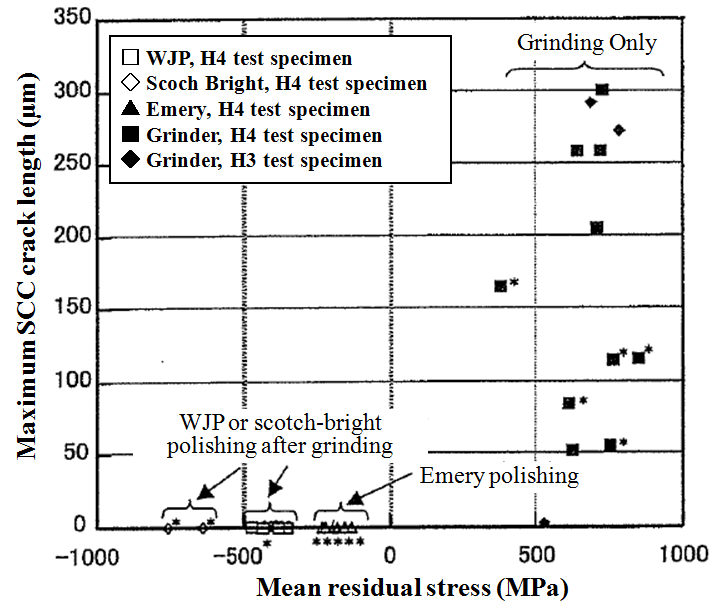

Fig. 1 Improvement of Surface Residual Stress and SCC Prevention by Internal Polishing |

||||

|

|

||||

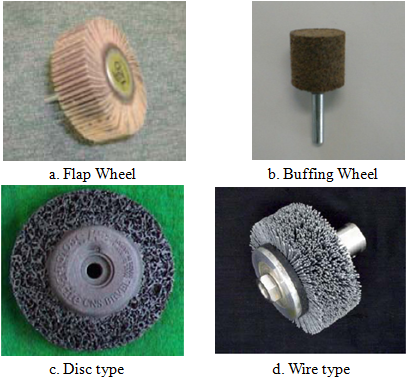

Fig. 2 Sample of whetstone |

||||

| 2. Scope | ||||

(1) Components |

||||

| 3. Features | ||||

(1) Prevent initiation of SCC crack at the sensitized zone. |

||||

|

|

||||

Fig. 3 Improvement of Surface Residual Stress and SCC Prevention |

||||

| 4. Examples of Application | ||||

| (1) This technique was applied to BWR PLR piping. (2) Same process has been applied to other components such as nozzle safe-end and Reactor Internals made of stainless steel. |

||||

| 5. Reference | ||||

| (1) Teruaki Sato, Kazuyoshi Yonekura, Satoshi Hongo, Shoji Hayashi and Hideyo Saito, ” Introduction of Repair/ Maintenance Techniques for SCC in Primary Loop Recirculation System Piping”, Maintenology,Vol.3,No.3(2004) ( in Japanese). (in English) (2) Kaneo Takamori et al, ”SCC Crack Initiation and Propagation of Low Carbonized Stainless Steel in High Temperature Pure Water”, Maintenology, Vol.3,No2(2004),( in Japanese). |

||||

| 6. Contact | ||||

| Japan Society of Maintenology (ejam@jsm.or.jp) | ||||

.png)

.png)