Nuclear Plant Service Engineering Co., Ltd. (NUSEC)

Classification

5 - A(Environmental improvement)

The Vacuum Blast Decontamination method is one of physical decontamination technologies to be performed on inner surfaces of pipes. We developed a special decontamination device based on this technology, and applied to pipes of actual power plants in the past. In these past field experiences using a conventional tool which was manually installed into pipes, positioned to working locations and removed from the pipes after decontamination procedure, we have recorded extremely higher radiation exposure of service technicians and the tool itself during each site work. To resolve this issue, we have developed a dedicated Remote-operated Vacuum Blast Decontamination Device.

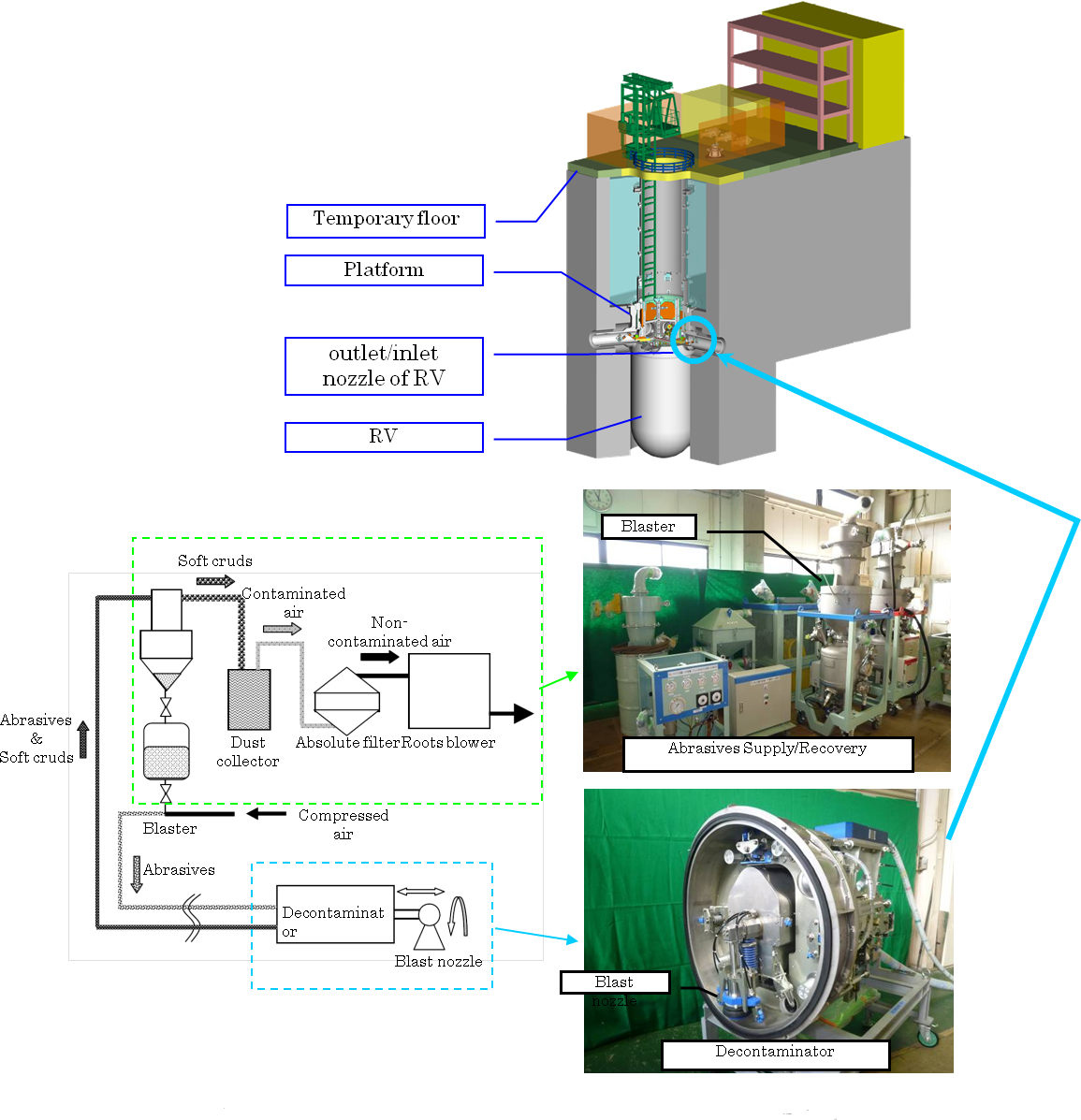

The Remote-operated Vacuum Blast Decontamination Device consists mainly of abrasives supply, collection system and decontamination system. Its configuration is shown in Fig 1.

Fig. 1 Remote-type vacuum blast decontamination system

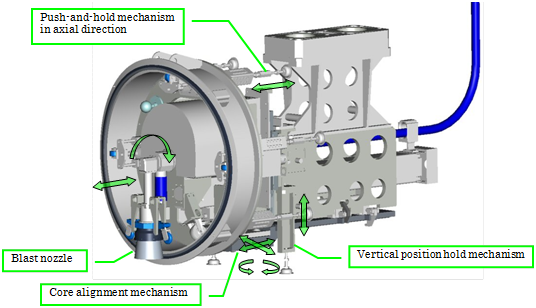

The decontamination device, newly developed this time, is designed to be installed directly into a pipe to be decontaminated and to accommodate a profiling operation of a blast nozzle on the pipe inner surface. The transmission shaft and rotary shaft featured with extension and retraction function are both equipped with driving shaft of the decontamination device in order to move mainly blast nozzle along the inner surfaces of pipe to be contaminated. As well as for the conventional tool, a driving shaft of the decontamination device is equipped with both a telescopic rotary shaft and a transmission shaft in order to achieve a profiling function of the blast nozzle.

In our latest contraption, we have developed additional mechanisms attached to the base decontamination device in order to accommodate a remote installation operation. This additional function gives us some great advantages below compared to the previous system:

- Remote alignment mechanism – this mechanism enables a remote operation for alignment between a shaft center of the decontamination device and a pipe to be decontaminated.

- Push-and-hold mechanism in axial direction against pipe end surface - this mechanism enables to prevent dispersion of abrasives by reducing any gaps between mating surfaces of pipe end surface and the blast nozzle.

- Vertical position hold mechanism – this mechanism is used to keep the decontamination device in its installed position during a blast decontamination.

The remote-type vacuum blast decontamination device is shown in Fig 2.

Fig. 2 Illustration of Remote-type vacuum blast decontaminator

With new three mechanisms above equipped to the decontamination device, works associated with installation / positioning / removal of the decontamination device and blast work execution by remote control. With this remote controlled operation, exposure of radiation associated with the works of installation / positioning / removal of the decontamination device was able to be reduced to less than 30%*1 when compared to those done with conventional decontamination device.

*1) This numeric value indicates the amount of reduction of radiation exposure involved in the installation / positioning / removal of the decontamination device, decontamination capability of conventional-type and remote-type is the same.

Phase 3 : Industrial Confirmation Phase

- (1) Components: Reactor Vessel (RV) of PWR

- (2) Location: Dissimilar metal welds of outlet / inlet nozzle of RV

- (3) Material: Applicable to any methods

- (4) Condition: In air

- (1)All works starting from installation / positioning / blast decontamination / removal of the decontamination device can be carried out in remote operation.

- (2)The abrasives supply, collection system can be placed as far as max 40m away from the Remote-type Blast Decontamination Device in operation.

- (3)Extremely low exposure will be achieved compared to using a conventional tool, since the decontamination is performed without dispersing abrasives and irradiated crud by using a dedicated blast nozzle which enables both injection and collection of abrasives simultaneously.

- (4)Radiation exposure associated with the works of installation / positioning / removal of the decontamination device was able to be reduced to less than 30% compared with the conventional device.

Fig. 3 Blast decontamination under way

The new decontamination device has been applied to RV inlet and outlet nozzles of three nuclear power plants in years since 2010.

- [1]Field Application of the Cladding of the PWR Reactor Vessel Outlet Nozzle Mitsubishi Heavy Industries, LTD Technical Review Vol.43 No.1 2006

Japan Society of Maintenology (ejam@jsm.or.jp)