Mechanical Maintenance and Engineering Section

Tomari Power Station, Hokkaido Electric Power Co., Inc. Japan

Classification

5 - A

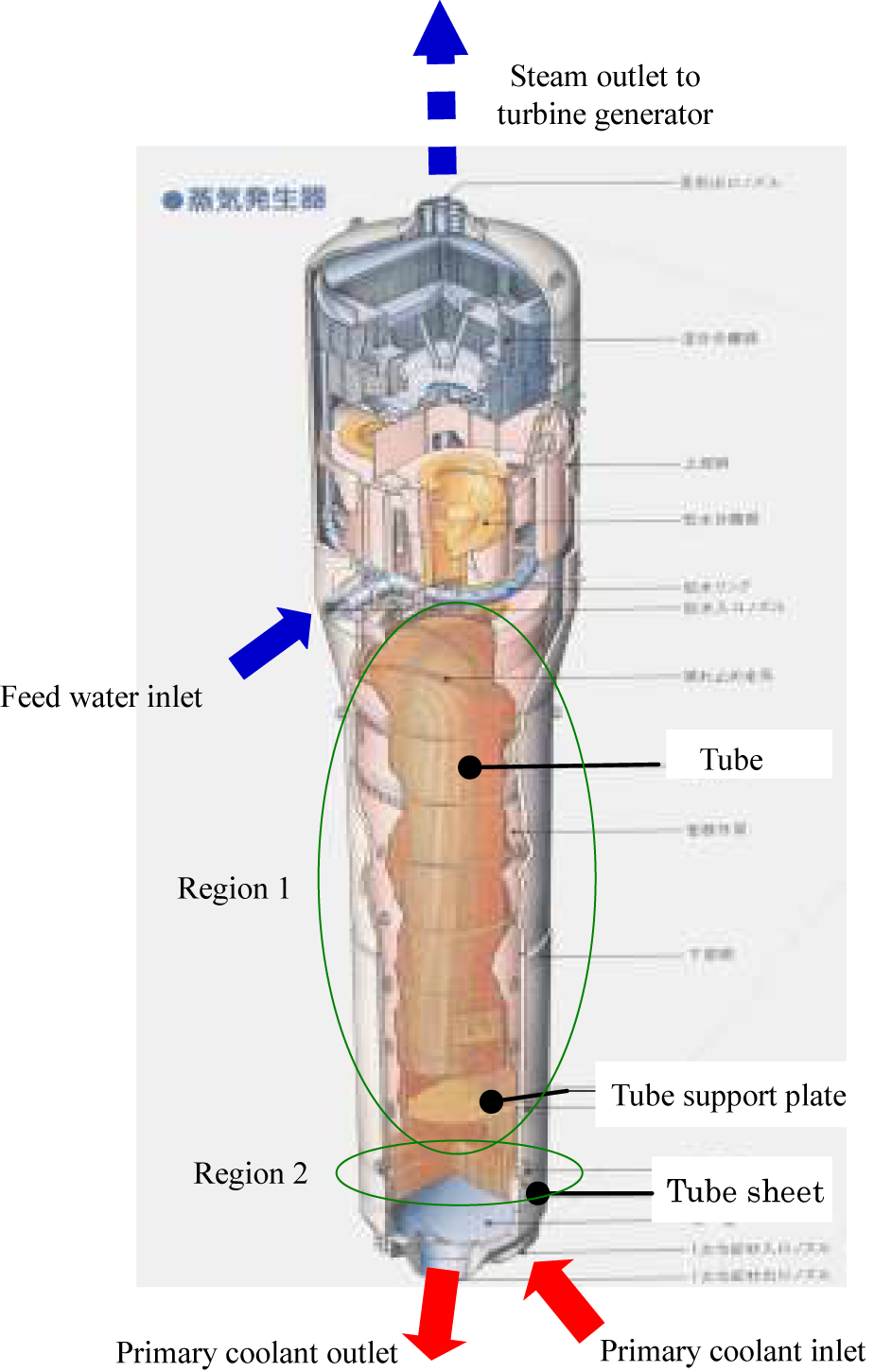

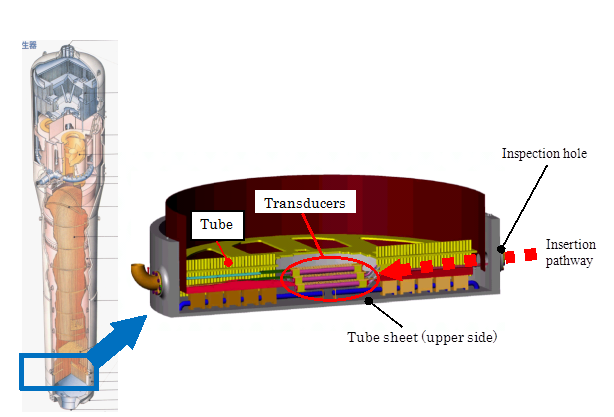

Tomari Unit 1/2 is Pressurized Water Reactor (PWR) and has Steam Generators (SGs), where thermal energy is transferred from primary coolant water to secondary coolant water.

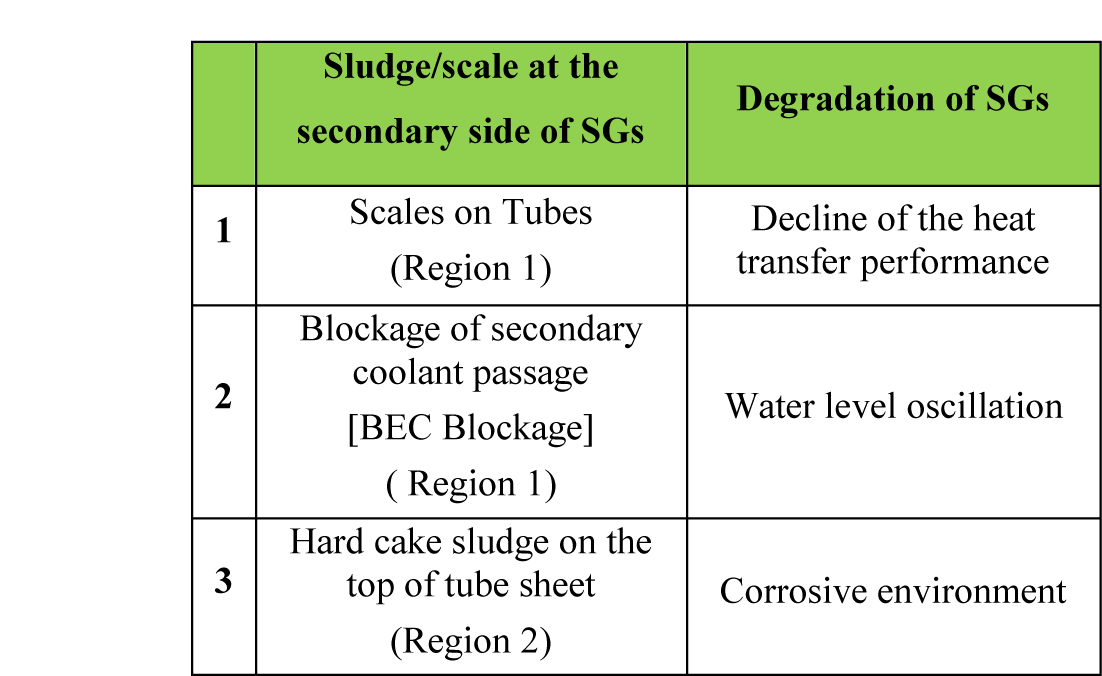

The secondary water contains a small amount of corrosion products from the equipment and tubes in the secondary system. With long run of power stations, the corrosion products are deposited at SGs as sludge/scale, and they result in a degradation of SGs (Table1, and Fig.1).

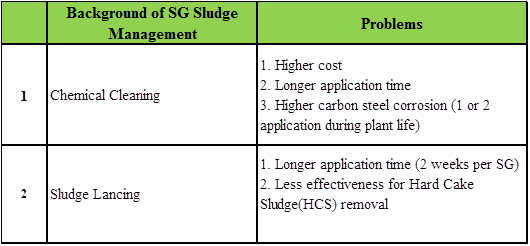

In the past, chemical cleaning or sludge lancing was adopted to remove the sludge/scale and to reduce the degradation of SGs, but these methods also have problems (Table2).

Fig. 1 SG of Tomari Unit 1/2

Table 1 The degradation of SGs caused by the sludge/scale deposition

Advanced Scale Conditioning Agent (ASCA) and Ultrasonic Energy Cleaning (UEC) are more effective, comparatively low-cost, and causing limited impact to outage schedules. Therefore, ASCA and UEC have been adopted as the official methods to remove the sludge/scale and to reduce the degradation of SGs in Tomari Power Station from 2005.

Table 2 Background of SG Sludge Management and their problems

- (1) Components: Steam Generator (SG)

- (2) Location: Secondary side

- (3) Material:

Inconel (Tube)

Carbon Steel or Low-alloy Steel (Others)

- (4) Condition: Listed Below including Applied Conditions of ASCA and UEC

- (1)Outline of ASCA

- ● Components:

・Top of tube sheet(TTS), Baffle plate, and Tube (Secondary side of SG)- ● Purpose

・Fe and Cu removal and transformation of scale property- ● Applied Methods

・Inject dilute chemicals to the secondary side of SGs- ● Applied Schedule

・The temperature of the primary coolant water is 80~40℃ (At the time of shutdown)

・First Fe ASCA, then Cu ASCA- ● Applied Conditions

・Concentration of the chemicals (EDTA) is 10,000ppm(Fe ASCA) or 2,300ppm(Cu ASCA)

・pH9(Fe ASCA) or pH 10(Cu ASCA)- ● Features

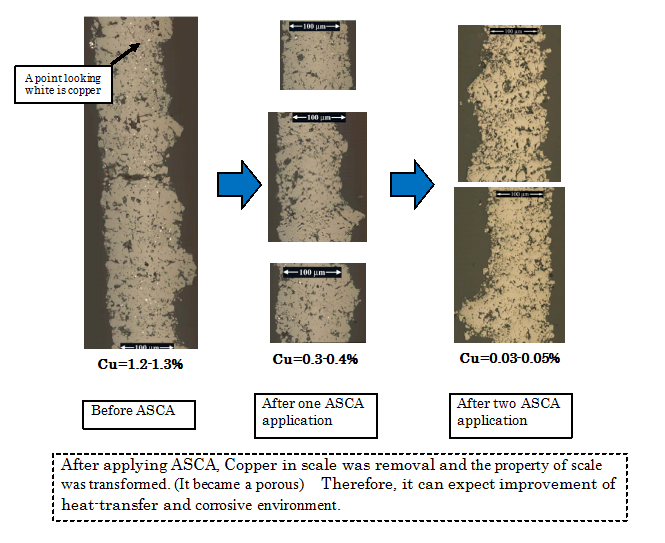

・Sink into and dissolve sludge/scale slowly, and transform the property of sludge/scale (Fig.2)

・Reduce the degradation of SGs such as low heat-transfer performance, BEC blockage, and corrosive environment (Fig.2)

・Because quantity of corrosion of the carbon steel is smaller than chemical cleaning, ASCA is applicable many times

・Low-impact to the outage schedule

Fig. 2 Tube scale after ASCA application

- (2)Outline of UEC

- ● Components:

・Top of tube sheet (Secondary side of SG)- ● Purpose

・Crush accumulated and hardened sludge at top of tube sheet- ● Applied Methods

・Insert UEC from inspection holes of the secondary side of SGs (Fig.3)- ● Applied Schedule

・After operation of ASCA is finished, bleed all the secondary coolant in SGs and then open the inspection holes- ● Applied Conditions

・Fill secondary side with water(more than UEC device level, and less than Flow distribution baffle level)- ● Features

・Ultrasonic waves generated by a wave generator disintegrate the sludge and make it fragile and easy to remove at the tube sheet of the secondary side of SGs

・After that, the sludge are ejected from SGs using Sludge Flush device

・Low-impact to the outage schedule

・The ultrasonic wave generators were originally developed for fuel cleaning

Fig. 3 Applying condition of UEC

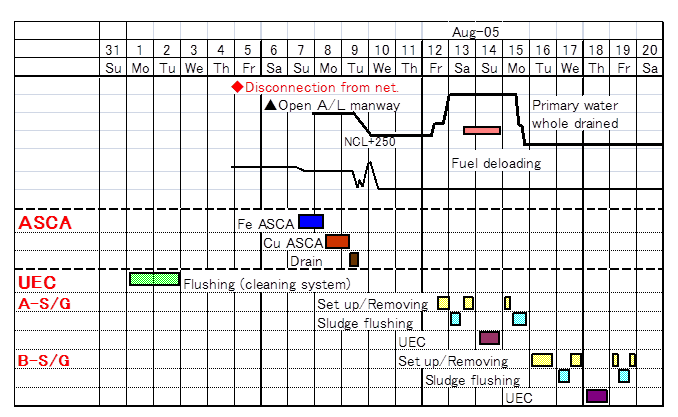

- (3)Sample schedule of ASCA/UEC

- ● Standard process of ASCA/UEC at Tomari Power Station is shown in Fig.4

- ● ASCA/UEC process is smart and has no impact to the outage schedule (in the case of Tomari)

Fig. 4 Standard process of ASCA/UEC at Tomari Power Station

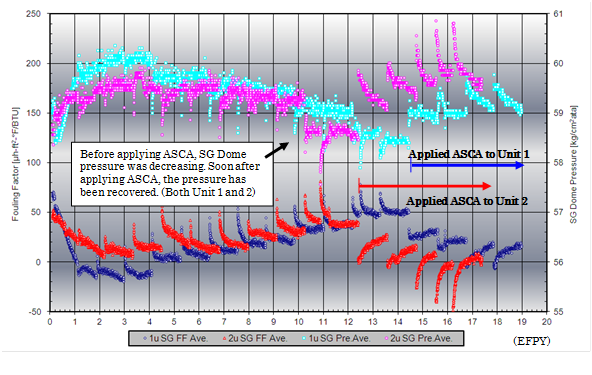

- (1) Effect of ASCA

・Increase of main steam (dome) pressure because of improvement of heat-transfer performance (Fig.5)

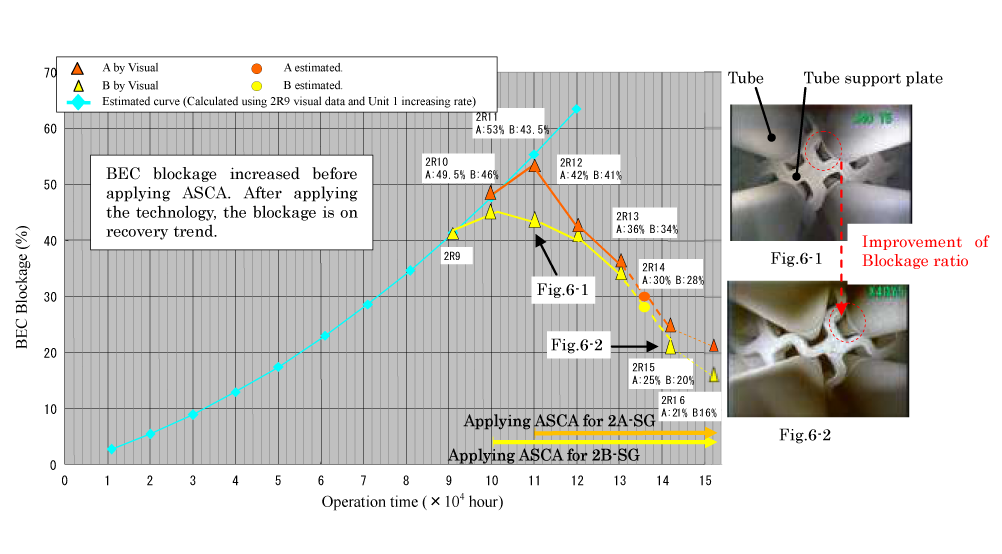

・BEC Blockage % is decreased, and Water level oscillation is not observed(Fig.6)

Fig.5 High heat performance after applying ASCA

(Increase of the main steam pressure)

Fig.6 Improvement of BEC blockage at baffle plate No.7 with repeated ASCA

(Tomari Unit 2)

- (2) Effect of UEC and ASCA

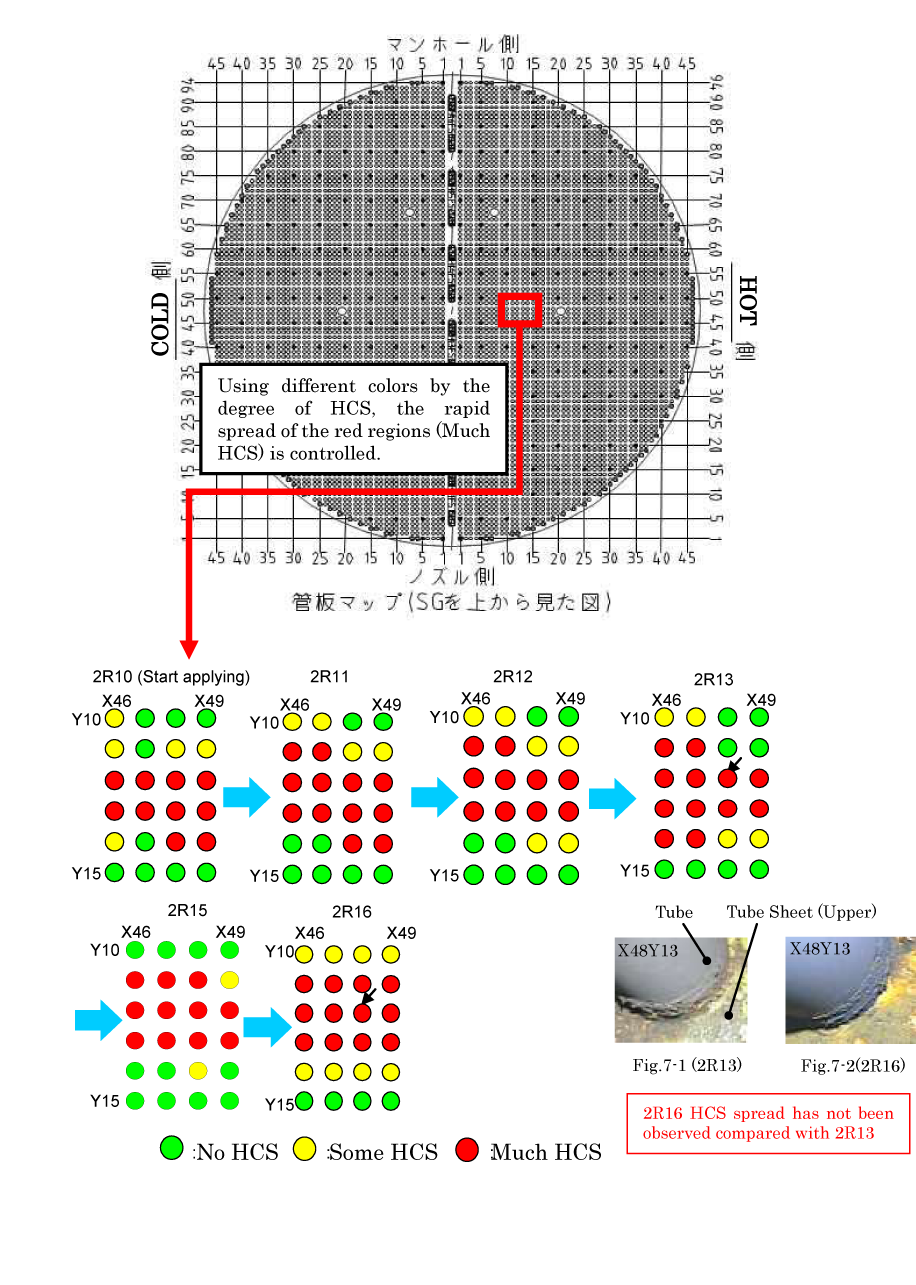

In the past, HCS spread was observed. After UEC/ASCA, HCS spread has not been observed, and UEC application prevents new hard cake sludge generation. (Fig.7)

Fig.7 TTS HCS region change

-

(1) ASCA technology for Tomari Unit 1/2

Since 2005 (Unit 1: 5 times, Unit 2: 6 times)

-

(2) UEC technology for Tomari Unit 1/2

Since 2005 (Unit 1: 4 times, Unit 2: 6 times)

- [1]Philip J.Battaglia, Donna L.Rogosky ; "The Use of Advanced Scale Conditioning Agents for Maintenance of the Secondary Side of Nuclear Plant Steam Generators", International Conference, Nuclear Energy for New Europe 2006(September 18-21,2006)

Japan Society of Maintenology (ejam@jsm.or.jp)