Classification

5 - A (Stress Improvement Technology for Reactor internals)

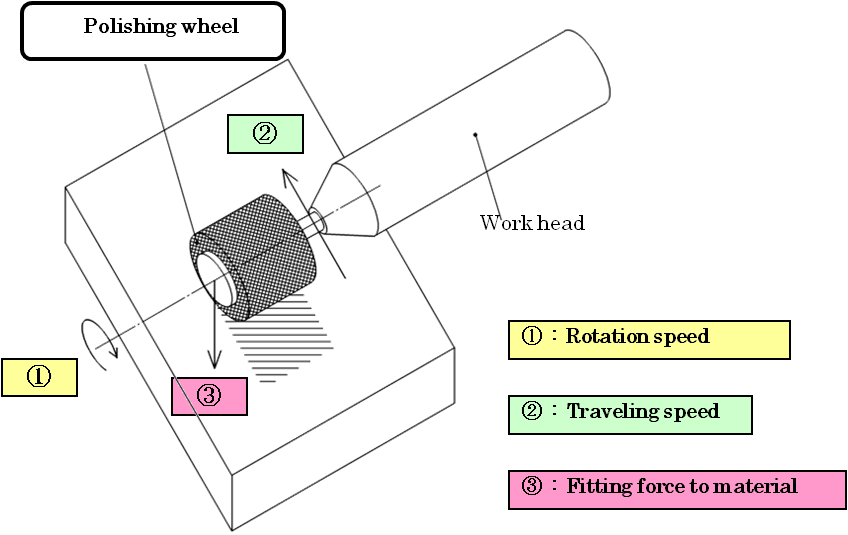

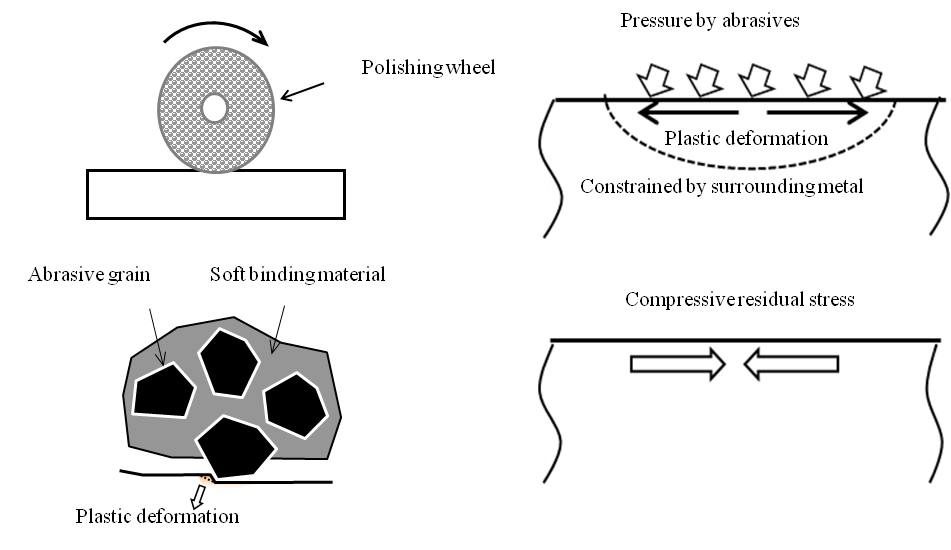

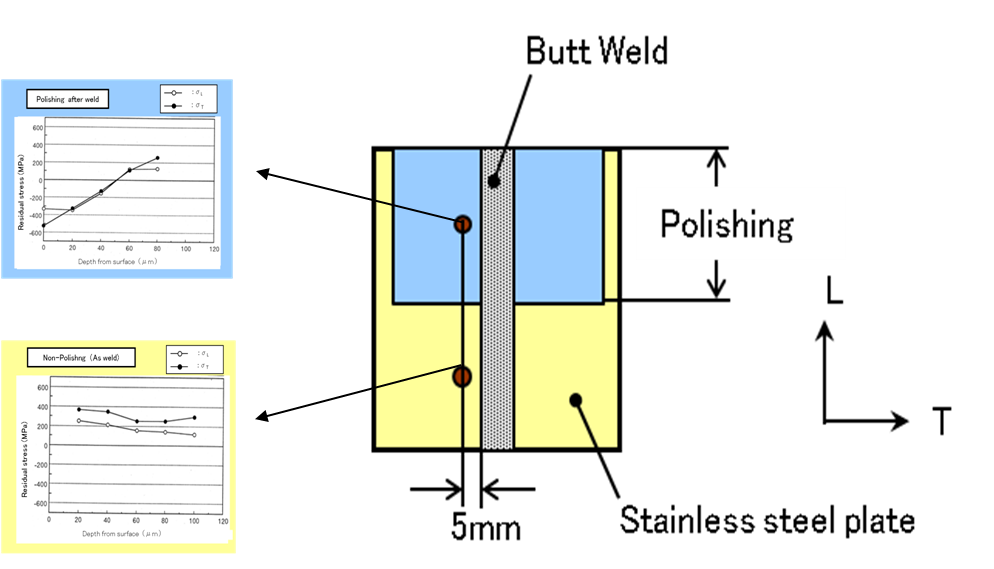

Mechanical polishing is generally applied in industry for the purpose of arranging fine configuration or smoothening surface. It also can make metal surface stress condition changing from tensile to compressive by some selected polishing wheels and optimum work parameters (Fig.1). Schematic of stress improvement mechanism by mechanical polishing is shown in Fig.2. Polishing wheel is composed of abrasive grains and soft binder. By rotation of polishing wheel, abrasive grains are beaten and pressed on the material surface. Then compressive stress appears on the material surface, because plastic deformation generated by abrasive grains pressure is elastically constrained by surrounding metal. The mechanical polishing is effective for preventing Stress Corrosion Cracking (SCC), whose potential can be mitigated by removing or reducing at least one of the three; aggressive environment, susceptible material and tensile stress.

Fig. 1 Schematic of stress improvement mechanism

Fig. 2 Schematic of stress improvement mechanism

Phase 3 : Publicity-accepted Phase

- Stress improvement by mechanical polishing has been applied, as a method of preventing SCC, to BWR and PWR plants in Japan, since 1990’s.

- The guideline of procedure to apply this technology to actual plants, based on studies and experiences, has been issued in Japan. [Reference [1]]

- (1)Material surface stress can be improved to several hundreds MPa in compression, and stress improvement range in depth can be reached to several decades of μm. Fig.3 shows stress distribution of core shroud weld mock up, for example.

Fig. 3 Stress distribution of core shroud weld test piece

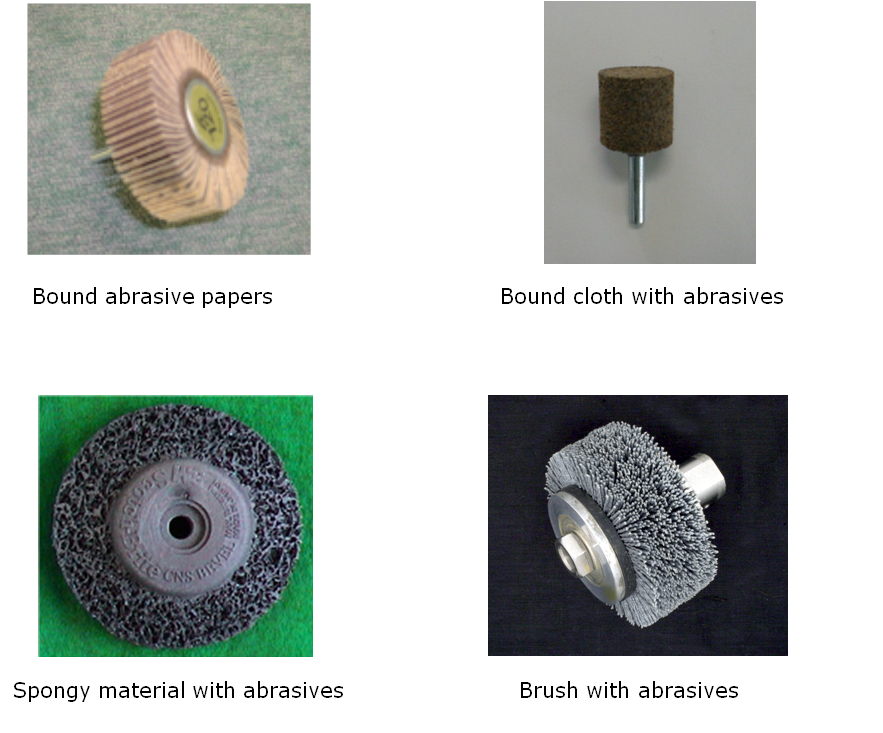

- (2)According to material and surface condition, various kinds of method (polishing wheel and work parameters) have been developed. Examples of effective polishing wheel are shown in Fig.4.

Fig. 4 Examples of polishing wheel effective for stress improvement

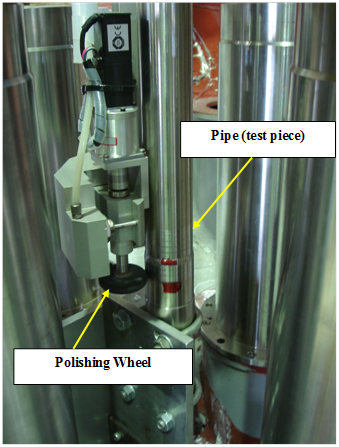

- (3)Polishing work is performed by operation of automatic device (Fig.5), or by human hands. Skillful workers, by using handy polishing tools (Fig.6), realize as effective stress improvement as automatic device.

Fig. 5 Mock up test using the automatic polishing device

for stress improvement of pipe weld

Fig. 6 A typical handy polishing tool

Concerning BWR plants of Japan constructed after 1990’s or core shroud replacement was performed, stress improvement by polishing has been generally applied to primary welds of core shroud. (Performer by Hitachi-GE Nuclear Energy, Ltd. or Toshiba Corporation)

In addition, there are some other experiences of application to such as nozzle weld of steam generator in PWR plant of Japan.(Performed by Mitsubishi Heavy Industry, LTD.)

- [1] Guideline for Preventive Maintenance Method “Stress improvement by mechanical polishing”, JANTI-VIP-10, JANTI (Japan Nuclear Technology Institute) (in Japanese )

Japan Society of Maintenology (ejam@jsm.or.jp)