| Vol.1 No.3 |

| Vol.1, No.4, NT17

|

Application of 3D Ultrasonic Inspection System for pipe wall thinning |

| TOSHIBA Corporation. |

KEYWORDS: |

| 1. Technical summary |

| Classification (I: Inspection, II: Repair, III: Replacement, IV: Preventive Maintenance, V: Others) |

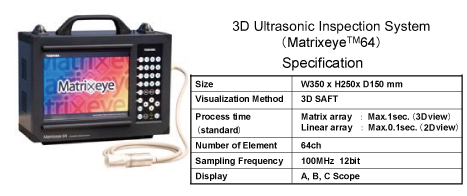

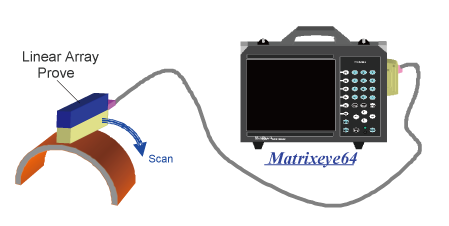

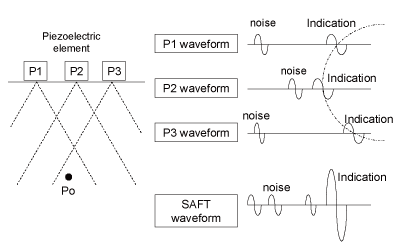

- 3D Ultrasonic Inspection System (Fig.1) has a feature that high speed inspection can be accomplished by using Phased Array Probe. This system has been applied for inspection of airplane parts (CFRP components), car components (aluminum die casting, spot welding), and pipe welding. - High speed, wide area inspection is possible by using 2D-SAFT method, which is one of the functions of 3D Ultrasonic Inspection System, for pipe wall thinning which includes local wall thinning. (Fig.2 and 3)

Fig.1 Overview of 3D Ultrasonic Inspection System

Fig.2 Example of system components

Fig.3 Principle of SAFT Method |

| 2. Scope |

(1) Components (2) Materials (3) Condition |

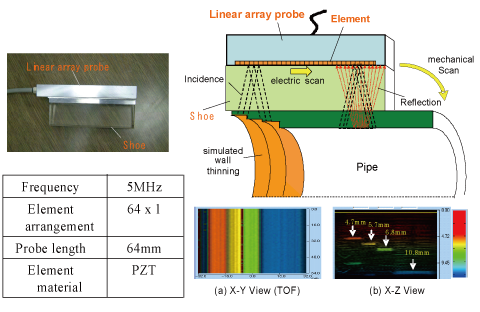

| 3. Features |

(1) The current UT inspection process for measuring wall thickness is by measurement of a single point. However, in the new 3D-UT inspection process, the system measures the entire area. (2) High speed, wide area inspection is possible by using SAFT method for pipe wall thinning which includes local wall thinning (Fig.4).  Fig.4 Overview of inspection of pipe wall thinning

|

| 4. Examples of Application |

A typical test result is shown below This process has been used three times in actual plant piping inspections.  Fig.5 Example of Application for 200A straight pipe (Manual scan)

Fig.6 Display of UT Result for 200A straight pipe (Erosion area)

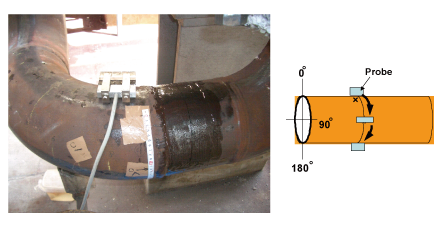

.png) Fig.7 Example of Application for 100A Elbow (using elbow scanner)

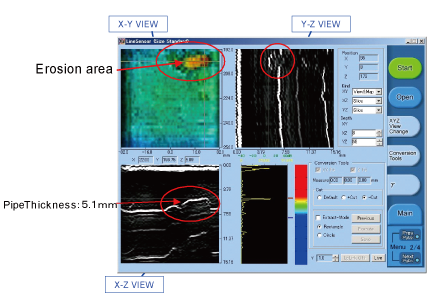

.png) Fig.8 Display of UT result for 100A Elbow (inside drill spot) |

| 5. Reference |

| (1) T.Sasayama, M.Katayama, T.Hamajima; "Application of 3D Ultrasonic Inspection System for pipe wall thinning", 1st co-operation lecture for inspection, evaluation and Maintenance, Japan Society of Maintenology, 2008(in Japanese) |

| 6. Contact |

| Japan Society of Maintenology (ejam@jsm.or.jp) |