| Vol.1 No.3 |

| Vol.1, No.4, NT16

|

Wall thinning inspection technique for large-diameter piping by a partially attached-type guided wave sensor |

| Hitachi, Ltd. Hitachi-GE Nuclear Energy, Ltd. |

KEYWORDS: |

| 1. Technical summary |

| Classification (I: Inspection, II: Repair, III: Replacement, IV: Preventive Maintenance, V: Others) |

Guided wave inspection by an ultrasonic wave propagated towards an axial direction is applied to detect the locations and cross section area of wall thinning in structures suck as piping (Fig.1). Over several dozen meters can be inspected at one time by attaching the sensor to part of the piping. Therefore, the inspection procedures can be rationalized by cancelling such incidental tasks like the heat insulator removal or installation of scaffolding to better access the piping. In particular, a partially attached-type guided wave sensor offers a great benefit for the rationalization, in the case of inspecting large structures like large-diameter piping.

.png) Fig.1 Schematic of guided wave inspection |

| 2. Scope |

(1) Components (2) Materials (3) Condition |

| 3. Features |

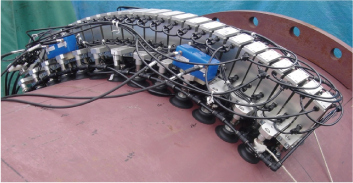

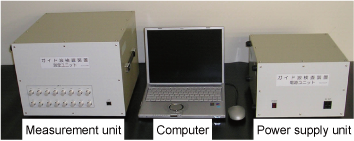

・No needs of large sensor for all around the piping  Fig.2 Partially attached-type guided wave sensor (Attached on 1100 A piping)  Fig.3 Guided wave inspection system |

| 4. Examples of Application |

・Guided wave inspection adopting the partially attached-type guided wave sensor can detect wall thickness. The wall thinning position can be detected by moving the sensor circumferentially. A typical test result is shown in Fig.4

・No experience of application to actual plant piping inspection so far. _Location_of_wall_thinning_area_and_sensor_Circumferential_projection_of_piping.png) (a) Location of wall thinning area and sensor (Circumferential projection of piping) _Inspection_results_depending_on_the_sensor_position.png) (b) Inspection results depending on the sensor position Fig.4 Inspection example (500A piping, 9.5mm thickness, carbon steel) |

| 5. Reference |

M.Miki, Y.Nagashima, M.Endou, K.Kodaira, and K.Maniwa; “Wall Thinning Inspection Technique for Large-Diameter Piping using Guided Wave”, Proceedings of the 6th Annual Meeting, Japan Society of Maintenology, 2009 (in Japanese) |

| 6. Contact |

| Japan Society of Maintenology (ejam@jsm.or.jp) |