| Vol.1 No.3 |

| Vol.1, No.4, NT14

|

Mitigation for Flow Accelerated Corrosion by Oxygenated Water Chemistry (OWC) in PWR Secondary Cooling System |

| The Japan Atomic Power Company (JAPC) |

KEYWORDS: |

| 1. Technical summary |

| Classification (I: Inspection, II: Repair, III: Replacement, IV: Preventive Maintenance, V: Others(Operation Management)) |

|

Flow Accelerated Corrosions (FAC) have occurred on the inner surface of some carbon steel pipes of PWR secondary cooling system, and, therefore, they have been replaced with chromium-contained material pipes. Oxygenated Water Chemistry (OWC) is a promising environmental mitigation for FAC of carbon steel piping in PWR secondary cooling system. Condensate and feedwater systems are the most corrosive for FAC among single-phase flow systems in PWR secondary loop, because the magnetite film formed on the surface of the carbon steel has the maximum solubility at about 150ºC. Though high pH control by All Volatile Treatment (High AVT) is useful to suppress the whole surface corrosion in PWR secondary system, magnetite film created by high AVT has a limit to suppress the local corrosion such as FAC. Fig.1 shows an example of significant wall thinning even after High-AVT. Especially remarkable wall thinning occurred at position 5 and 4 of the upstream cross section A of the elbow due to the turbulence enhanced by an orifice located upstream as emphasized with pink color in Fig.1. OWC produces more defensive film of hematite on the surface of carbon steel and is effective to mitigate FAC. A trial OWC was performed at feedwater system of Tsuruga Unit 2 (PWR, 1160MWe) in 2007. Fig.2 shows the trial OWC setup in secondary loop. Oxygen was injected at deaerator outlet. Shaded area with pink color in Fig.2 is the objective parts to suppress FAC by the trial OWC. Dissolved Oxygen (DO), Fe concentration and Electrochemical Corrosion Potential (ECP) were measured at some points as shown in Fig.2. Very small amount of injected oxygen could be considered to change the surface oxide film drastically from magnetite to hematite, based on an observation of ECP as shown in Fig. 3. .png) Fig. 1 Change of wall thickness distribution at inlet of Elbow

.png) Fig.2 Trial OWC setup in secondary loop of Tsuruga Unit 2 .png) Fig. 3 Potential-pH diagram for water-iron system |

| 2. Scope |

(1) Components |

| 3. Features |

(1) Very small amount of oxygen .png) Fig.4 Calculated Oxygen levels along feed water train |

| 4. Examples of Application |

|

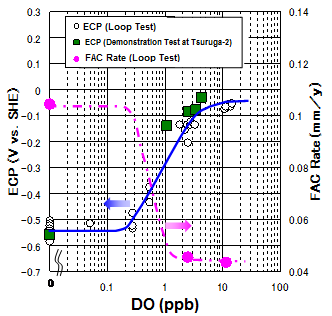

JAPC conducted trial OWC at feed water system of Tsuruga Unit 2. ECP measurement at inlet and outlet of high pressure feed water heater was also performed at this trial. The evaluation result shown in Fig.5 demonstrates that ECP (HPH) was remarkably raised by just a few-ppb oxygen injection. FAC rate and ECP were observed in FAC test loop under simulated AVT condition (180ºC, 5m/s, 500hr, pH9.2@ 25ºC. N2H4=0.1ppm). Demonstration ECP data at Tsuruga-2 showed good agreement with loop test data.

Fig. 5 Behaviors of ECP and FAC rate as a function of DO concentration Fig.6 shows the results of DO concentration and ECP measurement during trial OWC at Tsuruga-2. DO concentration at Feed Water Booster Pump Outlet (FWBPO) was high enough to suppress FAC of piping, and that at HPH outlet was low enough to avoid influence on SG. Measured ECP at HPH outlet did not change after oxygen injection though that at HPH Inlet increased. This ECP behavior suggested that oxygen injected was consumed within HPH and did not transfer into SG. Particulate Fe in feed water was sampled and analyzed at Tsuruga-2. As shown in Fig. 7, Fe oxide form was remarkably changed by OWC from magnetite to hematite in feed water system, but no change was observed at SG outlet. This result also shows the effectiveness of FAC suppression in feed water system piping and no influence on SG integrity. .png) Fig.6 Oxygen and ECP behaviors during trial OWC at Tsuruga-2 .png) Fig.7 Morphology change in particulate Fe in feed water at Tsuruga-2 |

| 5. Reference |

| [1] W. Sugino et.al., Effect of Water Chemistry Improvement on Flow Accelerated Corrosion in Light-Water Nuclear Reactor, Asian Water chemistry Symposium 2009. [2] H. Takiguchi, Oxygenated Water Chemistry for PWR Secondary System - New Approach to FAC -, NPC’08, Berlin, Germany, September 2008 |

| 6. Contact |

| Japan Society of Maintenology (ejam@jsm.or.jp) |