Hitachi Research Laboratory, Hitachi, Ltd. (HRL)

GE-Hitachi Nuclear Energy America, LLC (GEH)

Classification

5 - A(Environmental improvement)

Chemical decontamination is widely used to reduce dose rate of equipment and piping. However, it is not easy to keep low dose rate after the following operation especially in HWC (Hydrogen Water Chemistry) and NMCA (Noble Metal Chemical Addition) applied plants. Then, a new Pt deposition treatment method, what is called an Enhanced Low Temperature NobleChem™ (ELTNC), after chemical decontamination has been developed in order to reduce recontamination and provide continuity with IGSCC mitigation simultaneously during the following operation. This method is the improved version of LTNC developed and applied to actual plants by GEH. The ELTNC process provides plants with the capability to establish IGSCC mitigation much earlier than the 90 days which plants have to wait to perform the next OLNC (On-Line NobleChem™)injection of the following cycle.

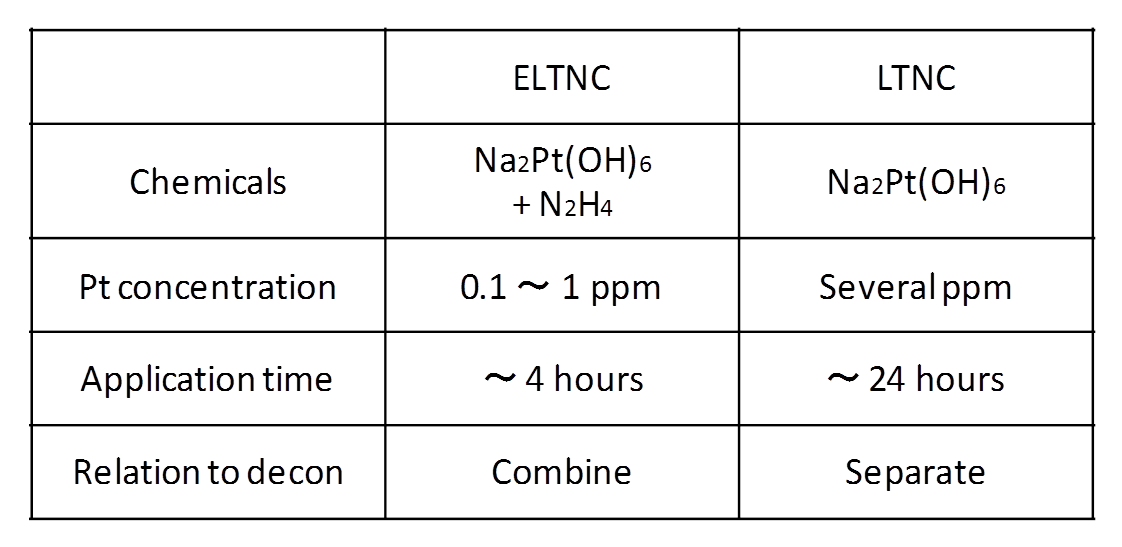

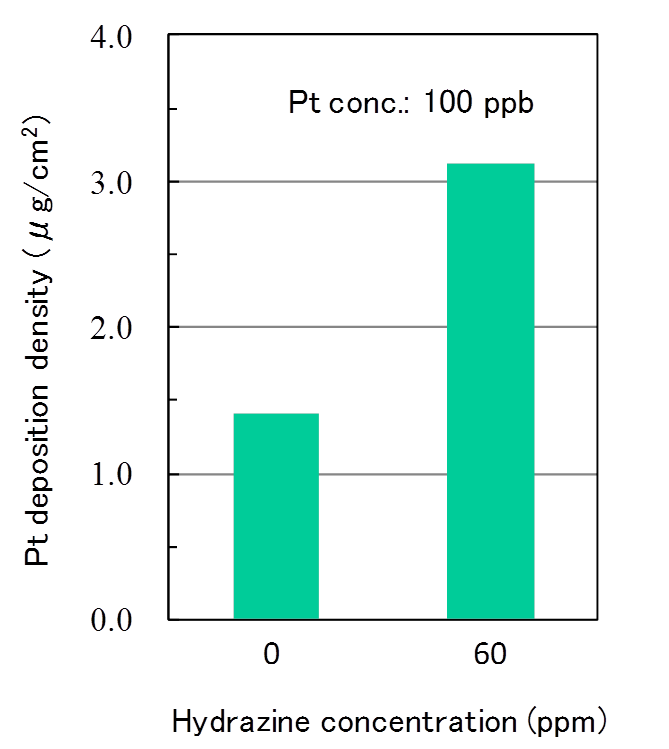

The ELTNC treatment conditions are shown in Table 1 compared with LTNC. Pt is supplied in the same chemical form of sodium hexahydroxyplatinate as LTNC. However, ELTNC treatment uses hydrazine to enhance Pt deposition at lower Pt concentration. This hydrazine enhance effect was confirmed by the laboratory test. The Pt deposition amount became twice by adding hydrazine as shown in Fig. 1. The enhance effect is not only to increase Pt deposition amount but also to accelerate the Pt deposition rate. So, ELTNC process needs shorter application time.

Table. 1 Pt deposition process condition

Fig. 1 Effect of hydrazine addition on Pt deposition

The reduction effect of Co-60 deposition was also confirmed by the laboratory test. Polished type 316 stainless steel coupons were prepared and some of them were OLNC treated in the test loop before the Co deposition test. Water chemistry conditions to simulate HWC were as follows: Dissolved oxygen, hydrogen and hydrogen peroxide were below 5 ppb, 100 ppb and 0 ppb (no addition), respectively. Zn was injected to target a concentration of 5 ppb. The test was conducted up to 500 hours at 553 K. Test results are shown in Fig. 2. The Co-60 amount on the coupon with Pt was about 40 % smaller than on the coupon without Pt at 500 hours.

Fig. 2 Effect of Pt on Co-60 buildup

The idea of that Pt would reduce Co-60 deposition on the decontaminated surface was confirmed by the in-plant tests. Coupons pre-filmed under the NWC conditions were prepared and half of them were treated by the HOP (Hydrazine, Oxalic acid and Potassium permanganate) chemical decontamination method. Both of these coupons were set in the MMS (Mitigation Monitoring System) just before OLNC applications were performed in the Cooper and River Bend plants. These coupons were removed from the MMS after about 7 months after the OLNC application. Dose rate of the coupon were measured. Though the absolute value of dose rate was not similar in the coupons from the two plants, in both sets of coupons the dose rate of the decontaminated coupons was about half of that of the pre-filmed coupons as shown in Fig. 3. These results indicate that the presence of platinum before an oxide layer is generated reduces the amount of Co-60 incorporation and are consistent with the laboratory experiment.

For NMCA applied plants, chemical decontamination means the removal of Pt from the material surfaces which results in the little SCC mitigation under low hydrogen injection rate. Though LTNC is the countermeasure of this problem, it needs more time for its application which is performed separately after the chemical decontamination. So, it is not applied since OLNC became popular. As OLNC is performed during power operation, plant materials can be protected after its application. However, there are at least 3 months for which SCC is not mitigated even if the OLNC application is planned after the chemical decontamination. ELTNC is effective not only to reduce recontamination, but also to mitigate SCC from the beginning of next cycle operation.

Phase 1 : Research and Development Phase

- (1)Components:

Primary system component and piping of hydrogen injected LWR

- (2) Location:

Primary coolant contact surface

- (3) Material:

Stainless steel

- (4)Condition:

In water at 363K

- (1)A new Pt deposition treatment can be carried out as a part of the chemical decontamination process using the same equipment for the HOP method.

- (2)Pt deposition occurs at lower Pt concentration by adding hydrazine.

- (3)Residual hydrazine after Pt deposition treatment can be decomposed by the same catalyst used for the HOP decontamination method to reduce secondary waste.

- (4)Co-60 deposition rate during the following operation can be expected to be 30 to 50 % reduction compared to that without Pt deposition treatment.

- (5)Pt deposition after chemical decontamination provides IGSCC mitigation much earlier than the 90 days which plants have to wait the next OLNC application of the following cycle.

ELTNC is developed to be combined with HOP method. HOP and ELTNC process for a future application is shown in Fig. 4. ELTNC step is performed after the last decomposition step of reducing agent. By applying ELTNC step at this timing, the heat up step and clean up step only for ELTNC application can be saved. In the ELTNC step, Pt is injected in the chemical form of Na2Pt(OH)6, then hydrazine is injected to enhance the Pt deposition. Treatment term is about 4 hours. After the Pt deposition, residual hydrazine is decomposed by using the same catalyst used for HOP and hydrogen peroxide to reduce secondary waste.

- [1] M. Nagase et al., “DOSE RATE REDUCTION METHOD FOR NMCA APPLIED BWR PLANTS”, Nuclear Plant Chemistry Conference, Paris, France, 24-27 September, 2012