Nuclear Plant Service Engineering Co., Ltd. (NUSEC)

Classification

6 - A(Others)

(1) Measurements and Databasing of 3D as-built data

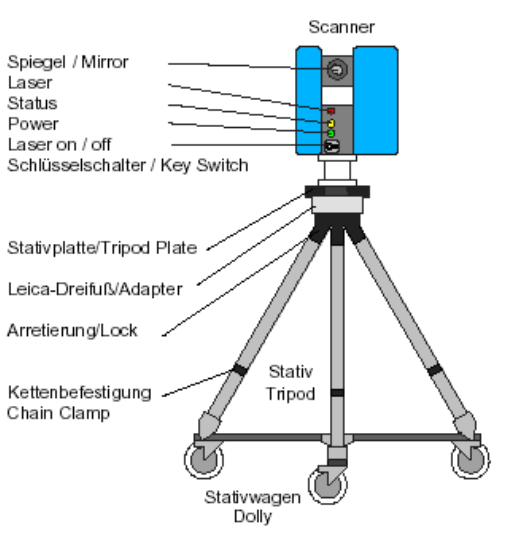

3D (3-Dimensinal) as-built data of components and piping that are installed at the Nuclear Power Plants have been actively employed for relocation / piping design or work planning in remodeling works. In order to make it effectively, 3D laser scanner (Fig.1) and digital camera have been in practical use.

Fig. 1 Appearance of 3D Laser scanner

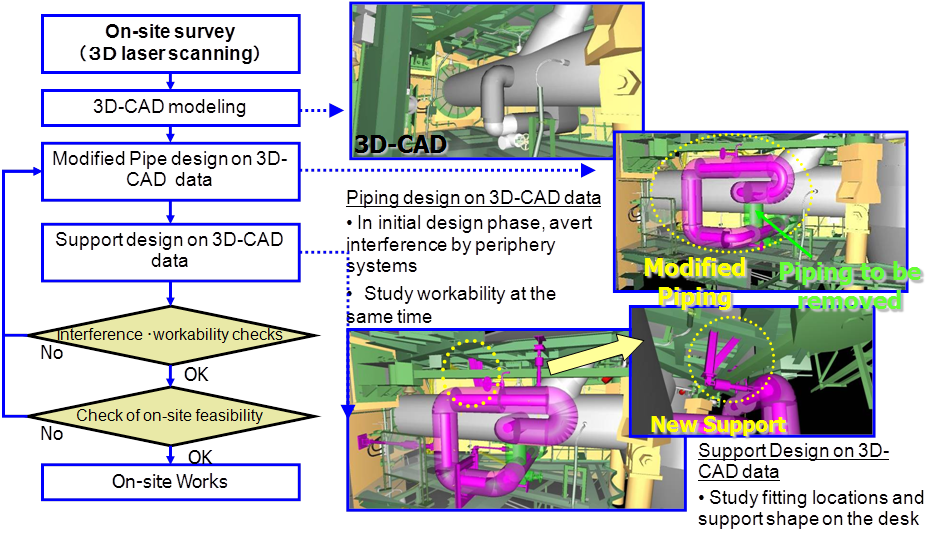

Measurements of as-built data is carried out by a team of 4 workers and it takes 5 to 10 minutes for laser scanning and panoramic photo taking at one measurement point, which is including movement and arrangement at a location. It is able to measure at 30 through 50 points per day. 3D point cloud data is a set of positional information of laser-scanned structures, which could be processed to 3D model. It requires 10 to 15 days or so to make 3D models at approximately 50 measurement points although it is depending on the targets. By super-positioning the processed 3D model over CAD model of newly installed piping or supports, the piping route plan (interference of piping or workability of support) could be verified, which would contribute to becoming an effective tool for designing (Fig.2 & Movie). Moreover, 3D modeling employed in work planning would be able to contribute to reduction of the radiation exposure of workers as it could be confirmed easily the spot situation of high radiation area. By taking panoramic photo at approximately-same position and height as those of the laser scanner, it could complement visually hard-to-identify portion of 3D point cloud data scanned in advance.

Fig. 2 Example of utilization of 3D laser scanned result at Designing Section

Movie

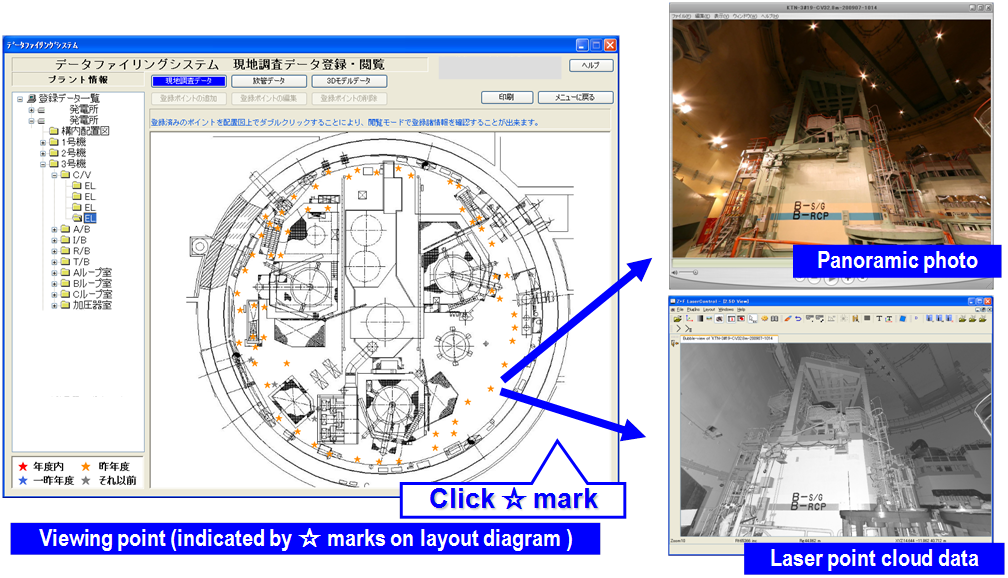

Locally laser scanned 3D point cloud data or panoramic photo have been databased for construction of a system to browse and manage them per plant (Fig.3). This system features in, simply by clicking star mark (★) on the layout diagram, being able to view panoramic photo taken at the spot out there and 3D point cloud data with ease and at a glance, which is now already adopted and being used by some of utility customers as a tool to make common use of as-built data within the radiation controlled area of the plant by both of the utility customers and us. This system features in the following functions.

Fig. 3 3D As-built management system

□ Panoramic photo browsing function

- This enables to make the feeling as if you are in the site, without actually entering there.

- Getting hold of conditions by plural workers is available without relying on human memory

- Grasping on-site work space (Interference check of brought-in equipments etc) is available.

- Utilization for remodeling the ancillary equipments like check-frame or stairs etc is available

(2) Further construction of the system eyeing for decommissioning

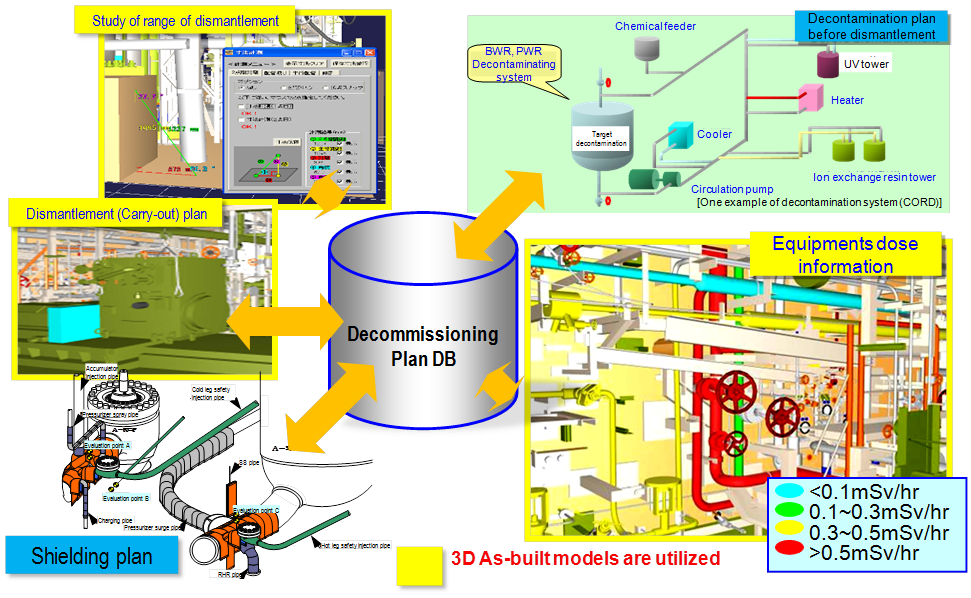

Constructing work assistance system for decommissioning of plant is now under consideration by applying this system, which is aimed to realize support system to effectively dismantle the plant and further to reduce wastes by effectively filling them into storage vessel (drum etc), by additionally putting into the system such data as dose equivalent rate, piping or existence of contamination, system name or information of required time for function maintenance at time of dismantlement (Fig. 4). Expansion of database region and amplification of contents of database for this purpose have been endeavored in order to cope with plan of the whole plant. This work assistance system is a system to enable all cooperative companies in concern related to decommissioning, let alone manufacturers in charge of designing, create / log plans of decommissioning based on these databases, confirm work instructions at the site and work track records by use of slate (tablet) PC at site. Thanks to this system, any working personnel ranging in broad work skill in a local site could access to the system.

Fig. 4 Overall view of Decommissioning Work Assistance System

Phase 3 : Publicly-accepted Phase

- This technique has applied in remodeling work of piping and support in Japan since 2006

- (1) Components: SSC(Structures, Systems and Components) of Nuclear Power Plant

- (2) Location: Anywhere

- (3) Material: Regardless of material

- (4) Condition: In air

- (1)Panoramic photos, 3D point cloud data and 3D model are all available to browse from uniformed management system.

- (2)Target objects could be retrieved as well, because property information and 3D models could be linked.

- (3)Fulfillment of database focused on decommissioning could make it effective work and reduction of wastes due to construction of the system.

- (4)Upgrades of works at site in liaison with slate (tablet) PC at site.

- (5)Reduction in radiation exposure of workers

Applied for CV and Loop chamber of nuclear power plant for period since 2006 through 2012.

- [1]T. Maruyama, The Situation of the Earthquake-Proof Reconstruction Construction using Laser Measurement, Society of Maintenology 6th Meeting, August 3-5, 2009

- [2]K. Okimura, T. Kobayashi, T. Tsuruta, J. Nishitani, M. Toyoda, MHI’s Maintenance Technologies Supporting High Plant Availability of PWR Nuclear Power Plants, Mitsubishi Heavy Industries Technical Review Vol.47 No.1, March, 2010

Japan Society of Maintenology (ejam@jsm.or.jp)