Classification

1 - B(Inspection Technology of SCC)

The eddy current testing (ECT) system has been established to inspect the surface of nickel based weld lines associating with for the structural integrity of nuclear reactor components.

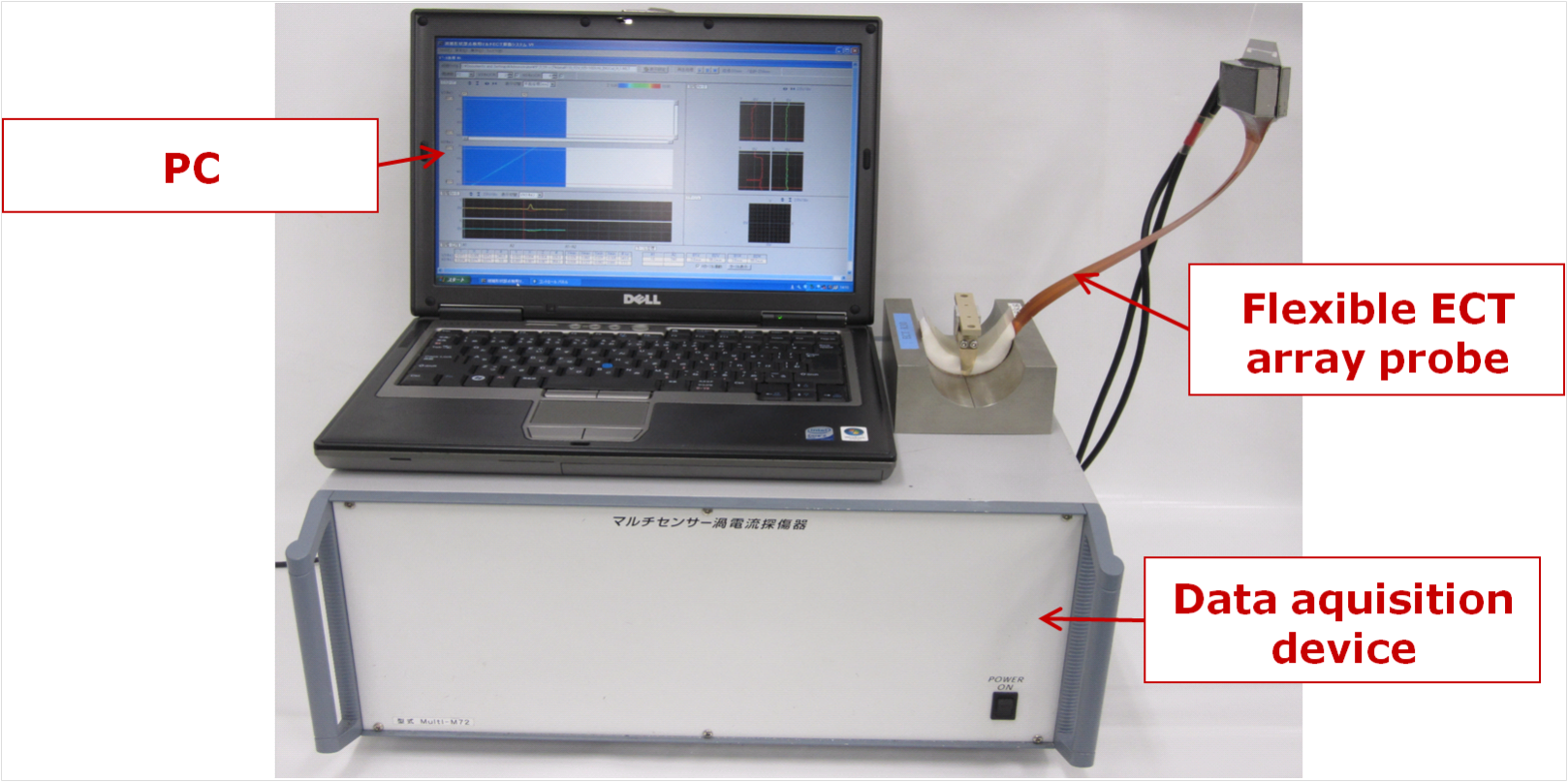

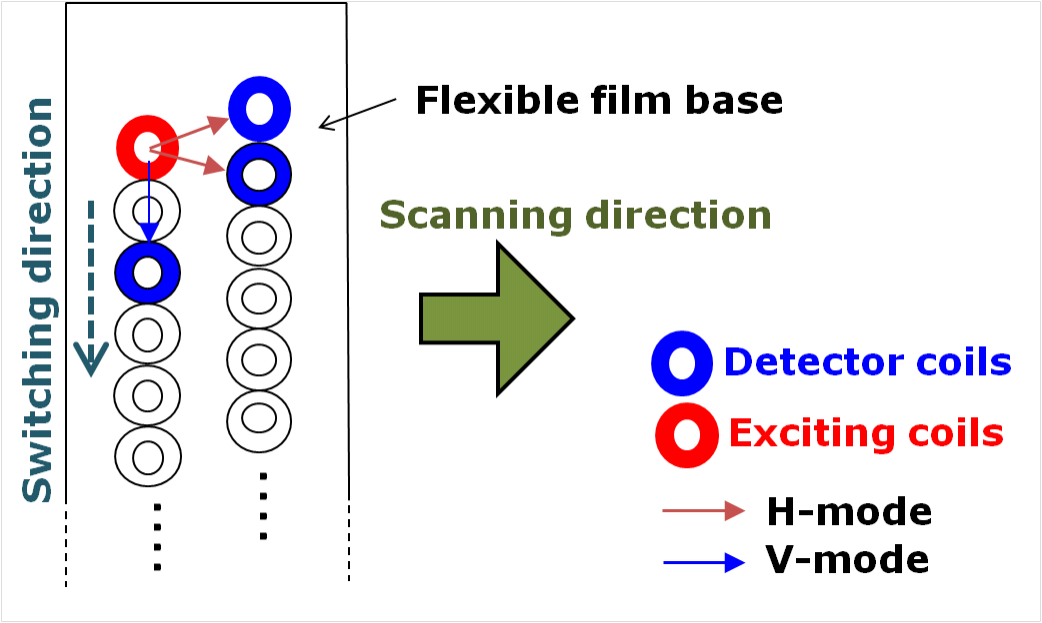

Fig.1 shows a view of ECT system. Fig.2 shows the structure of flexible ECT array probe. This system is composed of flexible ECT array probe, data acquisition device and personal computer(PC). The probe employing flexible technique performs stable scanning on three-dimensionally curved surfaces. The data acquisition device switches pairs of detector and exciting coils of probe in speedy succession, and then sends ECT signals of all detector coils to PC. The software installed in PC helps inspectors identify SCCs and measure their lengths.

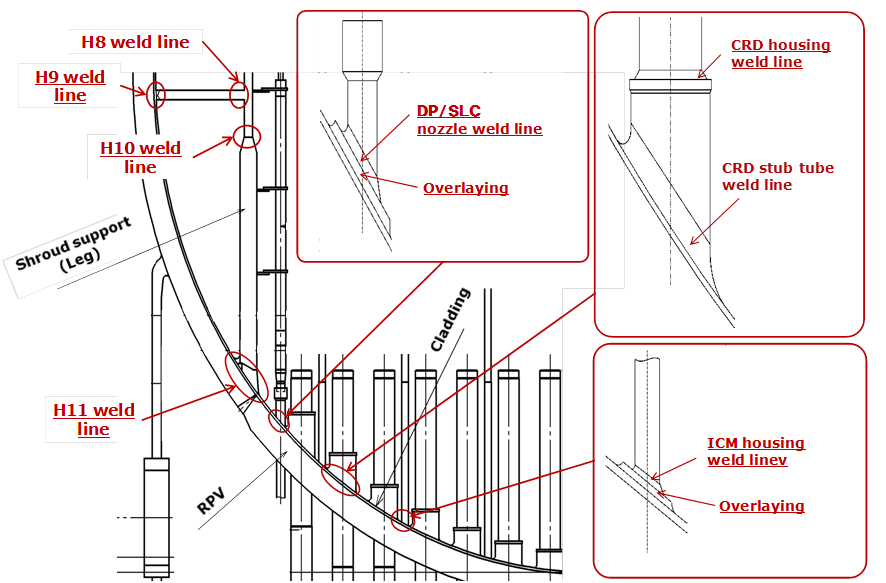

Fig.3 shows applicable nickel based weld lines of ECT system in BWR reactor. ECT’s performance, testing procedure and range of application have already been certificated by Japanese third party NDE(non-destructive examination) certification organization. Verfication has also been performed by using remote access devices and mock-up test pieces simulating in-vessel components of BWR.

As mentioned above, The ECT inspection has been established for nickel based weld lines of BWR’s in-vessel components. This system is also applicable to nickel based weld lines of PWR’s in-vessel components.

This is the method of improving residual stresses all around by moving the region irradiated by laser beam on the outer surface in the circumference direction. In addition, temperature increase by high energy laser is so high that inside water cooling can be omitted especially for a small pipe or nozzle.

Fig. 1 A View of the ECT system

Fig. 2 The structure of flexible ECT array probe

Fig. 3 Applicable nickel based weld lines of ECT system in BWR reactor

Phase 2 :Industrial Confirmation Phase

-The performance of detection and length measurement, testing procedure and range of application have been certificated by Japan Power Engineering and Inspection Corporation in January, 2011. In this certification, ECT has been performed for test pieces including mock-up test pieces simulating shroud support H9 and H11, CRD(Control Rod Drive) stub tube and ICM(In-Core Monitor) housing, in which SCC(Stress Corrosion crack) s are given.

- Mock-up testing by using remote access devices has also been performed. In mock-up testing, the remote access devices were operated under water, and ECT was performed for mock-up test pieces of BWR bottom head, such as CRD stub tube, ICM housing and DP/SLC(Differential Pressure and Standby Liquid Control) nozzle.

- (1) Components: In-vessel components of BWR and PWR having nickel based weld lines. (i.e., Shroud support, CRD stub tube, ICM housing, DP-SLC nozzle etc)

- (2) Material: Stainless steel, nickel based alloyts

- (3) Location: Nickel based weld metal, nickel base metal and stainless steel base metal

- (4) Condition: Both in air and under water

- (1)Flexible ECT array probe realizes speedy, high accurate and high quality inspection.

- A few line scans along weld line allow the inspection for whole area of weld line.

- Strong signal peaks occurring around surface edge of SCCs allow high accurate length measurement.

- Surface shape of weld line has no influence on the detectability and length measurement accuracy for SCCs .

- (2)The application software gives support to inspectors.

- The software includes the function to search for flaw signals and measure lengths of identified SCCs. Fig.4 shows an example of identification for SCCs on H9 mock-up test piece by the software.

- This software is in accordance with JEAG4217-2010[1], which is one of the Japan Electrical Association Guide and describes regulations in regard to ECT instrument.

![EJAM3-4NT42_Fig.4_An example of identification for SCCs[2]](Fig4.png)

Fig.4 An example of identification for SCCs[2]

The remote access devices has been established for BWR bottom head. Verification by using them has been performed for mock-up test pieces representing in-vessel components of BWR bottom head, such as CRD stub tube, and DP/SLC nozzle and ICM housing.

Fig.5 shows a view of ECT mock-up by a remote access device. Fig.6 shows an example of ECT image. This device is the multi-axial manipulator which is designed to be able to scan flexible ECT array probe on surface of nickel based weld lines of BWR bottom head. The manipulator type device can estimate three-dimensional coordinate of every coils of probe in combination with signals from several axes and surface shape information.

Therefore, ECT by the manipulator type device can give reasonably us so important information to repair as precise length, three dimensional coordinate and distribution of SCCs.

![EJAM3-4NT42_Fig5_A view of ECT mock-up [2]](Fig5.png)

Fig.5 A view of ECT mock-up [2]

![EJAM3-4NT42_Fig.6_An example of ECT image on curved surface mock-up [2]](Fig6.png)

Fig.6 An example of ECT image on curved surface mock-up [2]

- [1]JEAG4217-2010, Eddy Current Examination for Nuclear Power Plant Components

- [2]NDE symposium 2010, Tokyo, 13th December, 2010

Japan Society of Maintenology (ejam@jsm.or.jp)