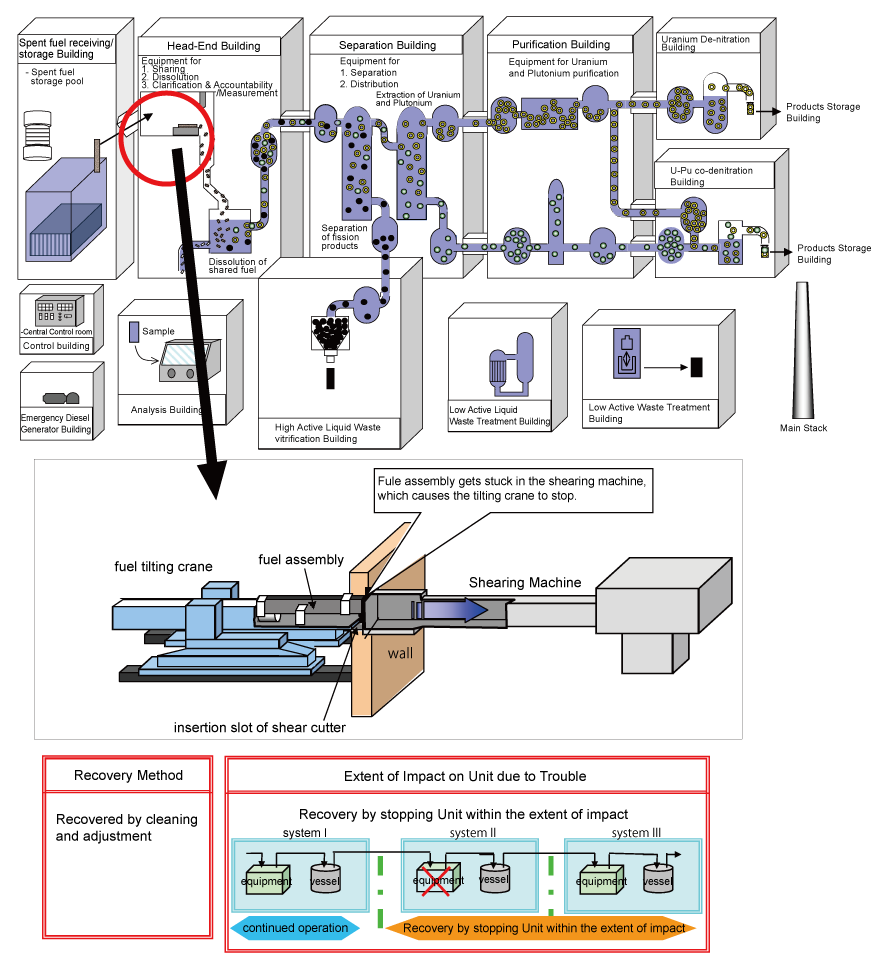

Attached 3: Potential troubles likely to occur at Reprocessing Plant and their countermeasure (No.3-02)

[Case: Fuel Assembly Gets Stuck in the Tilting Crane While pushing In]

| Case | Fuel Assembly Gets Stuck in the Tilting Crane While pushing In |  |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Outline of Incident | |||||||||||||

| (1) Where does it occur? | Fuel tilting crane in the Head-end building | ||||||||||||

| (2) Outline of the Unit | The crane inserts fuel assemblies from the spent fuel receiving/storage building horizontally into the shearing machine. | ||||||||||||

| (3) When does it occur? | During an operating of the tilting crane | ||||||||||||

| (4) How does it occur? | The fuel assemblies get stuck while being inserted into the shearing machine by the tilting crane. This leads the automatic shut down of the crane due to the overload. | ||||||||||||

| (5)Why does it occur? | Coincidental sticking of fuel assemblies due to the continuous operation of the crane. | ||||||||||||

| Impact due to the incident | |||||||||||||

| (1) On the outside of the Plant | There is no impact outside of the Plant; This is an incident which occurred at the cell in the Head-end building equipped with ventilation with filters to trap radioactive material, and during its related recovery work. Therefore no troubles such as release of radioactive material to the outside could occur. Further, this incident does not accompany leakage of radioactive material. |

||||||||||||

| (2) On safety | There is no impact on safety Since the tilting crane stops automatically due to overload from the stuck fuel assemblies, further development of the incident is not expected. |

||||||||||||

| (3) On workers | There is no impact on workers; Recovery works of the fuel tilting crane and the shearing machine are remote-controlled from outside of the cell. |

||||||||||||

| (4) On other processes | Down-stream processes could be affected; Due to the stop of the fuel tilting crane, down-stream processes could get some impact. Whether further down-stream processes are possible to be operated is judged based on the volume of the dissolution in the temporally-storage vessel installed between the Head-end building and the separation building. (Post-accountability Buffer Vessel). |

||||||||||||

| Outline of Corrective Measures | (1) The fuel assemblies are pulled back, then inserted again. (2) In case overload is not solved by re-insertion, misalignment between the fuel tilting crane and the insertion slot of the shearing machine shall be confirmed in alliance with the defined maintenance procedure, and position of the fuel tilt crane is adjusted. (Foreign materials inside the magazine shall be removed.) (3) After confirming that overload due to the inserted fuel assemblies does not occur, operation shall be re-started in accordance with the defined operation procedures. |

||||||||||||

| Announcement Category | Announced once a month after summarizing monthly(announced on Web-site) | ||||||||||||

| Information Category |

|

||||||||||||