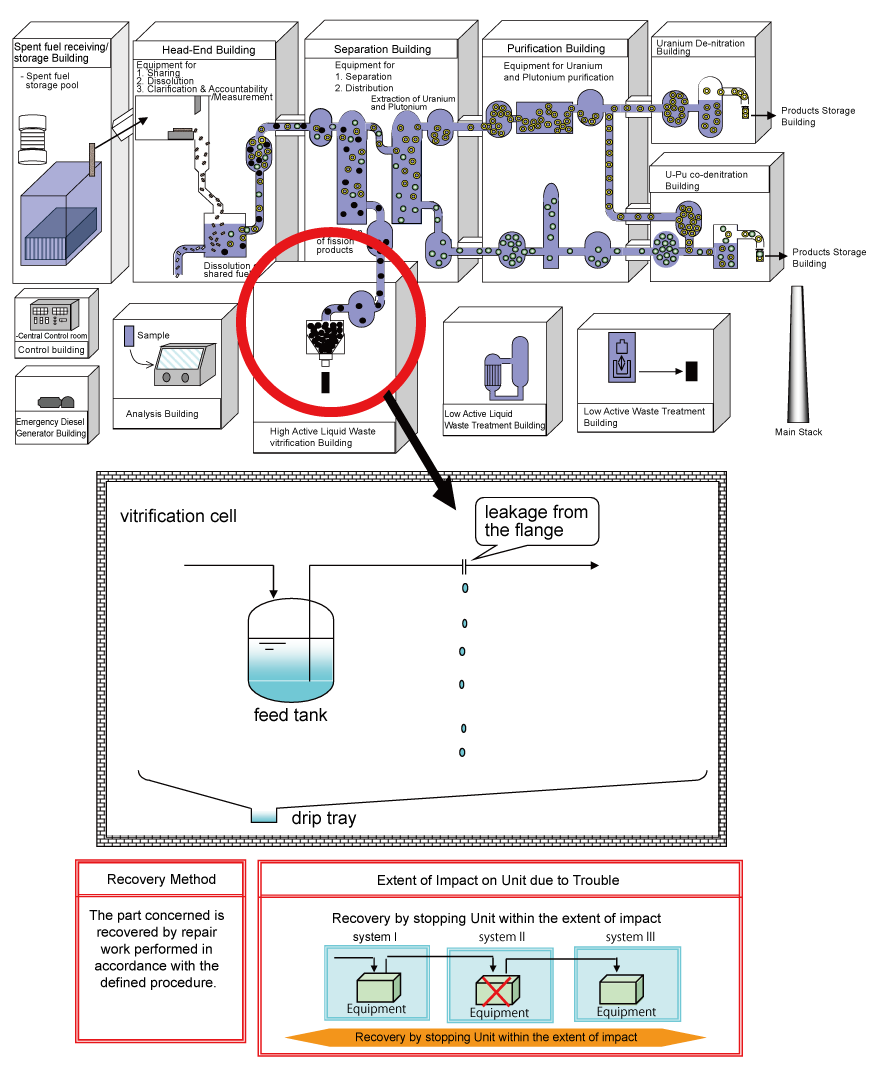

Attached 2: Potential Troubles likely to occur at Reprocessing Plant and their countermeasures (No. 2-22)

[Case: Leakage of High Active Liquid Waste in Vitrification Cell]

| Case | Leakage of High Active Liquid Waste in Vitrification Cell |  |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Outline of Incident | |||||||||||||

| (1) Where does it occur? | High Active Liquid Waste (HALW) Feeding Pipe in the (HALW) Vitrification Building | ||||||||||||

| (2) Outline of the Unit | The pipe which feeds HALW to the Melter. The pipe is designed to make remote-controlled maintenance possible, and can be taken off from flange depending on maintenance tasks. | ||||||||||||

| (3) When does it occur? | During the operation of the Melter | ||||||||||||

| (4) How does it occur? | HALW leakage occurred unexpectedly during the operation of the Melter. | ||||||||||||

| (5)Why does it occur? | Due to degradation of the sealing ability of packing on the flange | ||||||||||||

| Impact due to the incident | |||||||||||||

| (1) On the outside of the Plant | There is no impact outside of the Plant; This is an incident which occurred in the Cell where the Building ventilation system with filters to remove radioactive material is available, so that there is no impact such as the release of radioactive material outside of the Plant. Leaked HALW is treated properly in the HALW treatment building. |

||||||||||||

| (2) On safety | There is no impact on safety A drip tray and a leakage detector are installed in the cell, enabling leakage detection and recovering of leaked solution., while stopping the operation of the system concerned. This prevents the incident from further development, and thus, causes no impact on safety. |

||||||||||||

| (3) On workers | There is no impact on workers; The recovery task of the leaked solution is remote-controlled from outside of the cell. |

||||||||||||

| (4) On other processes | Up-stream and down-stream processes could be affected; Due to the stop of the Melter, there could be some impact on up-stream and down-stream processes. |

||||||||||||

| Outline of Corrective Measures | (1) To stop transferring the solution, and to recover the leaked HALW. (2) To rinse the HALW attached on the equipment inside of the cell. (3) To restore the flange concerned after completion of rinsing upon confirming rinsing effects such as the reduction of the radioactive level of equipment inside the vitrifiction cell, and then, to restart operation of the Melter in accordance with the defined procedures. |

||||||||||||

| Announcement Category | Prompt announcement, regardless of night or holiday (Press release) | ||||||||||||

| Information Category |

|

||||||||||||