Takahiro IKEDA (Toshiba Energy Systems & Solutions Corporation)

Classification

7 - C

At the decommissioning of Fukushima Daiichi Nuclear Power Plant, dose rate monitoring of the work environment has become important to prevent unnecessary exposure for workers. As the decommissioning work progresses, the number of works under the high dose rate environment will inevitably increase. Certainly, these works will be conducted using remote-controlled robots; however, manual tasks, such as the installation and maintenance of apparatus, are absolutely necessary. Dose rate monitoring of the work environments is therefore essential.

Depending on the location, the restoration of infrastructure, such as AC power supply, may be insufficient, resulting in humidity and the other environmental conditions not being controlled. Under such situations, special operating specifications that completely differ from the conventional specifications will be needed for radiation monitoring. Representative examples of special specifications include battery operation, wireless communication, drip-proof structure, and ease of installation.

Conventionally, battery-operated radiation monitors have been temporarily used for a short period of work. These monitors can operate only for several days before requiring battery replacement. The elimination or minimization of battery replacement tasks in high-dose-rate environments is an important issue to avoid unnecessary exposure of workers.

Given this background, we recently developed a power-saving and wireless radiation-monitoring system that can operate without battery replacement for an extended period.

- (1) Components:

radiation-monitoring system for radiation-controlled area

- (2) Location:

N/A

- (3) Materials:

N/A

- (4) Condition:

N/A

(1) Basic Design

In the present work, the functions necessary for a radiation monitor were compiled on the basis of the specifications defined in the Japanese Industrial Standard [1], which was newly issued in April 2017, for portable area radiation monitors. With regard to power saving, the target battery replacement interval was set to longer than 6 months on the basis of the site requirements.

To achieve this target interval, we adopted not only common power-saving electronic devices and circuits but also an intermittent measurement as an operation mode and an active-sleep technique. In this operation mode, the dose rate measurement and communication for a certain amount of time are repeated periodically according to set values. During the time between each measurement/communication cycle, the devices (measurement module) enter the active-sleep state. The time between measurement/communication cycles can be set to arbitrary and effective values.

Generally, in the case of Internet of Things (IoT) systems in which various power-saving sensors are used, continuous monitoring is required because the event to be monitored will occur at random. However, in the case of radiation monitoring, an intermittent measurement mode can be adopted. The monitoring period is usually set according to the objective or the situation to monitor the dose rate in areas. This approach is quite different from the system design of IoT, which is why the intermittent measurement mode can be adopted in radiation monitoring.

In the active state, first measurements are performed for a preset time. Then, calculations are conducted. Next, bidirectional communications with a centralized monitoring PC (main unit) are conducted. Communication is conducted in conformity with the international communication standard for wireless communication [2] [3] [4]. Further, each device enters the active-sleep state until the next wakeup time defined by a set value.

To suppress extra power consumption due to collision detection and retrying via wireless communication, the monitoring system is operated after the transmission timing between each device (measurement module unit) and the centralized monitoring PC has been appropriately set in advance.

The measurement module unit contains a real-time clock (RTC) for controlling power and time in the active-sleep state. The RTC is driven by a coin-type battery mounted on each circuit board. Furthermore, the time synchronization between the RTC and the monitoring PC is executed by broadcasting the time synchronization command from the monitoring PC all at once. The synchronization is performed at the preset timing once per day, when the monitoring PC and all measuring modules are in the communication state.

Although secondary batteries can be used as the power source, multiple dry batteries, which are primary batteries, were ultimately used because they are readily available even in an emergency situation and because their recharge process, unlike that of secondary batteries, does not require cumbersome management. Regarding the use of dry batteries, we also implemented a function to predict battery replacement timing. Generally, the discharge characteristics of a secondary battery such as a Li-ion battery feature a linear decrease with respect to the square root of elapsed time (½ power law). In this study, we found that an alkaline dry battery would exhibit the same characteristics as a Li-ion battery, and on the basis of this characteristic, we designed a function to predict the replacement interval of batteries through extrapolation.

When the voltage of the battery falls below a certain threshold (3.3 V) along the ½ power law, another accelerating effect is added to the ½ power law. The voltage will reach the “end voltage,” which is defined as the lower limit value for the normal operation of the dry battery. However, in this newly developed system, we use 3.3 V as the voltage for replacing the battery instead of the end voltage.

Using the ½ power law combined with the voltage for replacing the battery, we predicted the time interval between battery replacements by extrapolation of the successive least-squares fitting for linear expression.

(2) Device Configuration

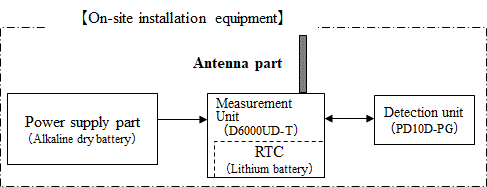

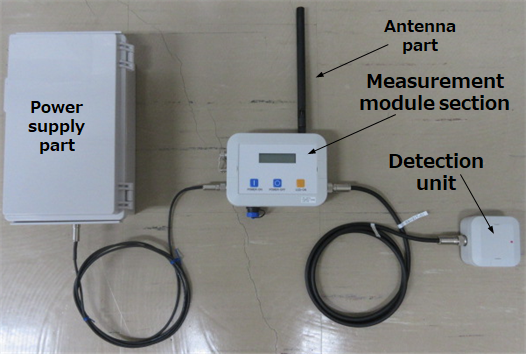

The newly developed measurement apparatus for the system comprises a detection unit, measurement module unit, and a power supply unit. This apparatus was designed to retain its portability and workability during battery replacement. These apparatus will be installed in the areas to be measured. Fig. 1(a) shows a schematic of the system configuration for the measurement equipment, and Fig. 1(b) shows a photo of one of the units.

Fig. 1(a) Schematic of on-site installation.

Fig. 1(b) Photograph of on-site installation equipment.

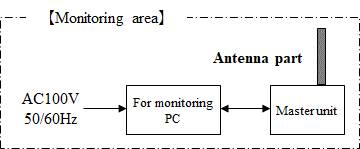

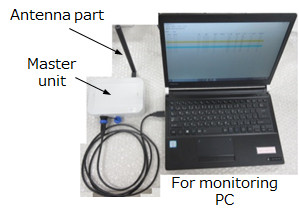

The centralized monitoring PC and a parent device for the communication (main unit) will be installed outside the measurement area to monitor all measured data. Fig. 2(a) shows a schematic and Fig. 2(b) shows a photo of these devices. In addition, weatherproof, waterproof packaging meeting standard IP 67 [5] was adopted given the environmental conditions such as humidity at the installation location.

Fig. 2(a) Schematic of a monitoring area installation.

Fig. 2(b) Appearance of the monitoring area installation equipment.

The measurement module unit comprises an arithmetic/control processing unit for controlling signal processing and monitoring the operation mode from the detection unit, a wireless transmission unit for transmitting calculation results and battery information, and the RTC unit for performing schedule management of the intermittent operation.

An LCD displaying the dose rate and parameter values and an ON/OFF switch for performing power-supply operations are mounted on the surface of the measurement module. To lower power consumption, the LCD display turns off the backlight normally and turns on the backlight manually only when confirming the display contents. Nine single batteries (type D) are built into the power supply unit as three in series, three in parallel.

In a typical installation, multiple detection units, measurement module units, and power supply units are installed at arbitrary locations to be monitored and the dose rate and battery voltage are read out from the monitoring PC with the parent devices. The monitoring PC and the parent device require a commercial power supply.

When the equipment installed at the site and the monitoring PC are in communication status, the operation mode and the set value for each measurement module unit can be changed manually from the monitoring PC.

5. Performance Test

5.1 Test Overview

The performance of the developed system as a radiation monitor was examined on the basis of standard JIS Z 4344: 2017 [1] for portable area monitors. For power saving, experiments involving battery discharge as functions of operating temperature and duty ratio of the intermittent measurement mode were carried out.

For the temperature-dependence tests, three batteries (type D) were built into the power supply unit and the unit was installed inside a thermo-hygrostat. On the basis of the technical specifications of the batteries, we conducted the tests under two temperatures: −10°C and +45°C. The temperature of −10°C was the lower operating limit, whereas that of +45°C was the upper limit. The condition of −10°C represents the worst case because batteries generally discharge more rapidly at lower temperatures. In this test, the operation mode was 100% duty (continuous measurement).

For the test of duty dependence, two intermittent measurement modes were examined: 25% duty (6 h/day) and 4% duty (1 h/day). A duty of 25% assumes continuous work in the controlled area. The duty of 4% is the value assumed when substituting this system for the survey work conducted at least once per day for 1 h.

In this case, nine batteries (type D) were built into the power supply unit as three in series, three in parallel and the unit was installed inside a thermo-hygrostat. The test temperature was set to −10°C as the worst-case emulation.

5.2 Test Results

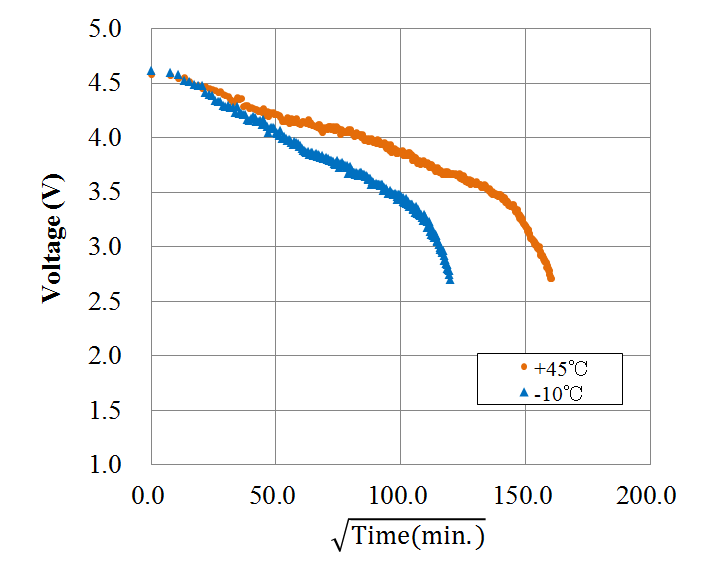

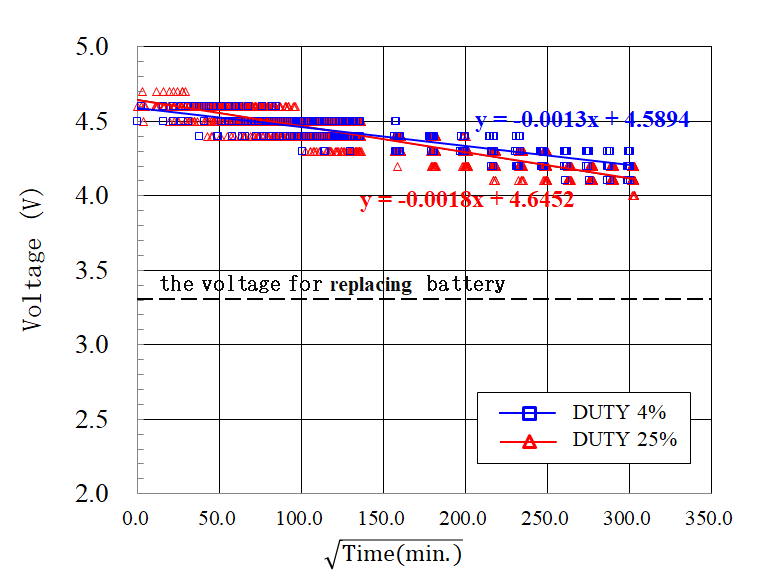

We carried out performance tests based on the specifications established in standard JIS Z 4344: 2017, which includes specifications for parameters such as energy response, dose rate response, and accuracy. As a result, we confirmed that the developed radiation monitor exhibits performance consistent with the aforementioned standard for a portable area monitor. In this paper, we present the results of power-saving tests in detail. Fig. 3 shows the results of the temperature dependency test, and Fig. 4 shows the results of the duty dependency test. The X-axis of both figures was drawn on the basis of the aforementioned ½ power of elapsed time (h).

Fig. 3 Temperature characteristics [measurement mode: continuous; temperature condition: −10°C and +45°C (using thermo-hygrostat)].

Fig. 4 Discharge characteristics by duty dependence [temperature: −10°C (controlled using thermo-hygrostat)]:

duty 4% and duty 25% (intermittent measurement mode: three series; three parallel power supply conditions).

As shown in Fig. 3, similar response profiles of the battery discharge curves are observed for −10°C and 45°C along the ½ power law. However, the curve corresponding to −10°C indicates more rapid discharging. This result is in agreement with the established knowledge concerning the temperature dependence of battery consumption. The operable time span without battery replacement at 45°C is apparently 1.7 times longer than that at −10°C.

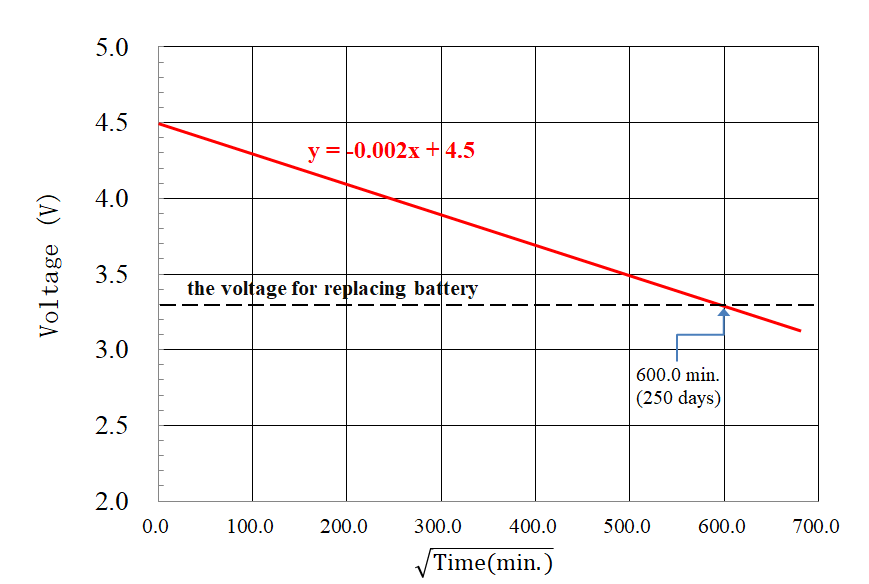

To clarify the duty dependence, least-squares-fitted lines were drawn in Fig. 4. Although a slight difference was observed in the starting voltage of the batteries, the gradient of the fitted line of the 25% duty was clearly large. The formulas of the fitted lines are shown in Fig. 5. In the case of the 25% duty, the slope of the fitted line was −0.0018. As a conservative evaluation, we assumed the slope and the starting voltage to be −0.002 and 4.5 V, respectively. The voltage at which a battery is replacing battery is 3.3 V, as previously described. Thus, the characteristic discharge function under the conditions of 25% duty and −10°C was obtained as

Y = −0.002X + 4.5, (1)

where Y is the voltage across the battery (V) and X is the 1/2 power of the discharge time (min). Using this formula, the elapsed time to reach 3.3 V (the voltage at which the battery is replaced) can be extrapolated, leading to an estimated elapsed time of 250 days. Thus, the system could be operated without a battery replacement for at least 250 days, even at −10°C. In the case of a normal temperature environment, we expect that the battery replacement interval would increase by several ten percent beyond 250 days.

Fig. 5 Discharge characteristics (extrapolation) by duty dependency [temperature: −10°C (controlled using thermo-hygrostat)]:

duty 25% (intermittent measurement mode: three series; three parallel power supply conditions).

5.3 Conclusion

We have developed a power-saving and wireless radiation-monitor compliant with standard JIS Z 4344: 2017 for portable area monitors. We adopted the intermittent operation mode and the active-sleep technique to the basic design and confirmed their effectiveness using two different experiments. The experiments confirmed that the newly developed radiation monitor can be operated without battery replacement for at least 250 days (8 months), exceeding our initial target of 6 months. We expect such power-saving and wireless communication features to reduce radiation exposure by saving labor, improve data reliability, and enable reliable remote monitoring.

Finally, we conclude that this system will be applicable to not only Fukushima Daiichi Nuclear Power Plant but also to other nuclear power plants, RI facilities, and laboratories.

6. Reference

- 1.“Transportable area monitor for X and γ rays” JIS Z 4344: 2017 issued by the Japanese Standards Association, (established April 20, 2017)

- 2.“Radio equipment for 920 MHz band telemeter, tele control and data transmission” ARIB STD - T108B Ver. 1.0, General Association of Radio Industries Association, (formulated February 24, 2012)

- 3.IEEE Std 802.15.4g-2012 (Amendment to IEEE Std 802.15.4-2011)

- 4.IEEE Std 802.15.4-2012 (Amendment to IEEE Std 802.15.4-2011)

- 5.“Degrees of protection provided by enclosures (IP Code)” JIS C 0920: 2003 issued by the Japanese Standards Association, (amendment July 20, 2003)

Japan Society of Maintenology (ejam@jsm.or.jp)