After local gas phase space is formed in the water, under water TIG weld is processed in that gas phase space. The welding method is TIG welding which is broadly used and has a higher heat input than that of laser welding.

However, if the condition of welding process is selected in broader range, high quality and stable welding process is possible and expected to be highly reliable crack seal welding procedure.

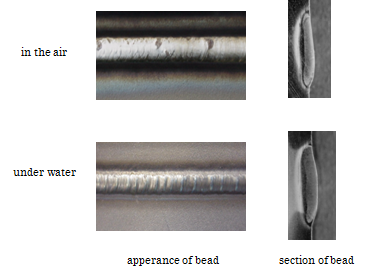

An appearance of welding bead and bead section after underwater welding procedure, are shown in Fig. 2. From this figure, it is confirmed that good welding is possible in the water.

|

|

|

| Fig. 1 Work of underwater welding |

Fig. 2 Welding mock up test result

(base metal : Alloy600) |

|