| GA 1 - 2 - 3 - 4 - AP 1 - 2 - 3 - 4 - 5 - NT 1 - 2 - 3 - 4 - 5 - 6 → Vol.1No.2 | ||||||

| Vol.1, No.1, NT1

|

||||||

Simulation Technique for UT Wave Propagation as an Effective Tool for Predicting the Inspection Results and Interpreting the Root Cause of Unexpected Indications |

||||||

| Ichiro KOMURA 1 and Takashi FURUKAWA 2 1Nondestructive Evaluation Center 2Japan Power Engineering and Inspection Corporation |

||||||

KEYWORDS: |

||||||

| 1. Technical summary | ||||||

| Classification (I: Inspection, II: Repair, III: Replacement, IV: Preventive Maintenance, V: Others) | ||||||

|

||||||

|

|

||||||

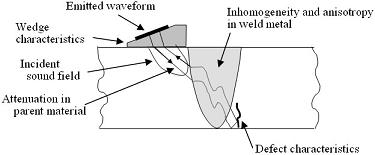

| Fig. 1 Factors which affect to the UT wave propagation(1),(2) | ||||||

| 2. Scope | ||||||

|

||||||

|

||||||

| 3. Features | ||||||

|

||||||

|

||||||

| 4. Examples of Application | ||||||

|

||||||

|

||||||

|

||||||

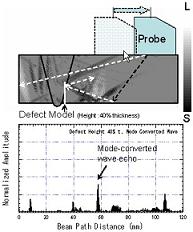

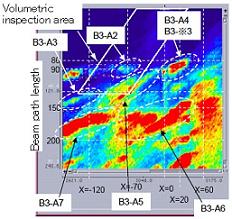

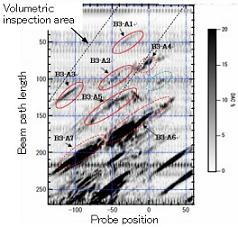

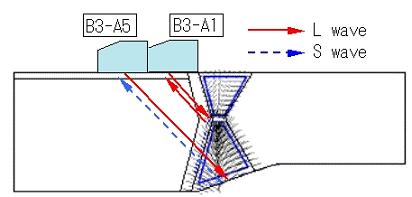

Fig. 8 Example for root cause investigation of indications(4) |

||||||

| 5. Reference | ||||||

|

||||||

| 6. Contact | ||||||

| Japan Society of Maintenology (ejam@jsm.or.jp) | ||||||